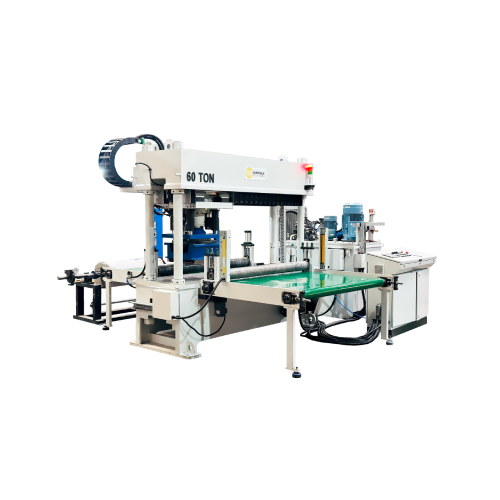

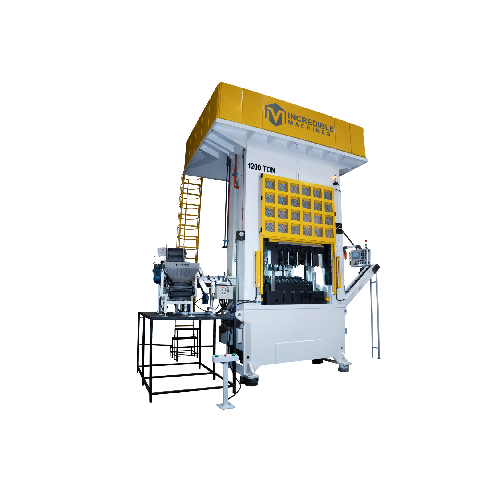

Annual Maintenance Contract (AMC) for Hydraulic Presses

At Incredible Machines Pvt. Ltd., we recognize that your hydraulic presses are crucial to your production efficiency. Ensuring their continuous, optimal performance is not just a service offering—it’s our responsibility. That’s why we provide a comprehensive Annual Maintenance Contract (AMC) designed to keep your machines operating at peak performance year after year.

Why Choose AMC from Incredible Machines?

We are among India’s fastest-growing manufacturers of high-precision, heavy-duty hydraulic presses ranging from 50 to 5000 Tons. Our AMC services are built on the same foundation of quality, reliability, and technical excellence. Here’s what sets us apart:

- Cutting-edge Infrastructure: One of the largest manufacturing plants in India, equipped with the latest machining, assembly, testing, and inspection facilities

- Expert Engineering Team: Highly trained engineers specializing in servo-hydraulics, deep drawing, composite moulding, and precision control systems

- PAN India Field Service Network: Dedicated service teams across major industrial hubs in India for quick response and support

- Global Service Experience: Successfully maintaining machines in USA, UK, Russia, Vietnam, Egypt, Oman, and more

- Tailored AMC Packages: Customized service plans based on machine usage, criticality, and production demand

Scope of AMC Services

- Preventive Maintenance Visits: Routine inspection, calibration, and maintenance activities scheduled quarterly, biannually or as per usage

- Critical Component Check: Inspection of main cylinders, servo systems, cushion mechanisms, and structural alignment

- Hydraulic System Audit: Pressure testing, oil health monitoring, leakage detection, and filter condition assessment

- Electrical and PLC System Diagnostics: Servo drive tuning, PLC function check, HMI updates, safety relay and sensor testing

- Lubrication System Check: Functionality check of manual/central/auto lubrication systems

- Consumable & Spares Review: Evaluation of wear-prone parts with replacement advice and priority supply

- On-Demand Emergency Support: Service engineer visits within committed timeframe for breakdown support

- Performance Benchmarking: Verification of output speed, accuracy (JIS Grade 2), and safety interlocks

- Detailed Reporting: Visit-wise machine health report, recommended actions, and service record

Key AMC Benefits

- Extended machine lifespan and improved ROI

- Reduced downtime and production loss

- Enhanced operator safety and performance reliability

- Compliance with quality and accuracy standards (JIS B6403)

- Priority access to technical support and spare inventory

Our Maintenance Infrastructure & Capabilities

- In-house Testing Bays for hydraulic, electrical, and control system simulation

- CNC & VMC Machining for part replacement and on-demand component manufacturing

- Spare Parts Warehouse with ready stock of critical components

- Remote Monitoring Capability (optional)

- Annual Technical Audits and machine performance certification

Employee and Client-Centric Service Culture

- Well-equipped field service engineers with tools, sensors, and safety kits

- Service engineer training programs for updated technologies

- Regular customer feedback sessions to improve service quality

- Transparent documentation and adherence to preventive schedules

Get in Touch

Let our experienced service team take care of your machines so you can focus on what you do best — production and growth.