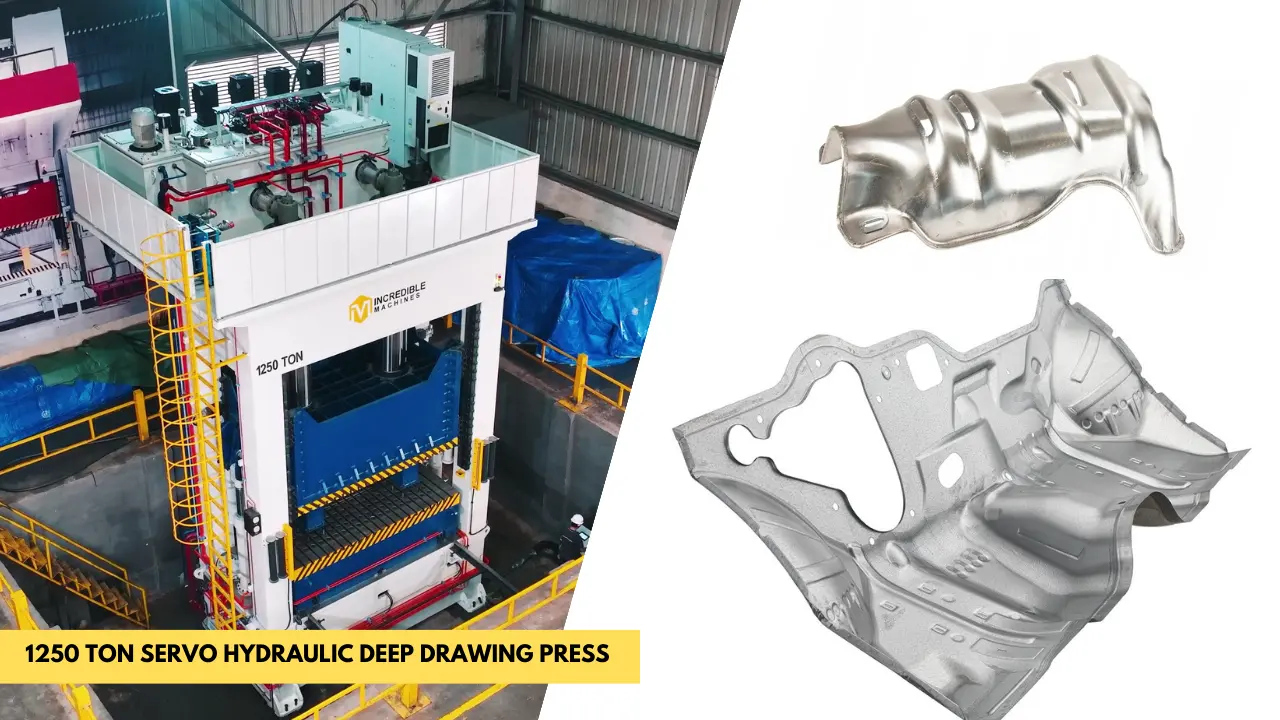

Precision Hydraulic Solutions for High-Accuracy Cold Forming Applications

At Incredible Machines Pvt. Ltd., we design and manufacture fully customized hydraulic cold forging presses engineered for extreme precision, high force, and long-term reliability. Built for demanding industrial environments, our cold forging presses are ideal for producing dimensionally accurate, high-strength metal components without the need for elevated temperatures. Whether you're forming fasteners, shafts, or precision mechanical parts, our presses are optimised for exceptional performance, energy efficiency, and minimal material waste.

Applications & Use Cases

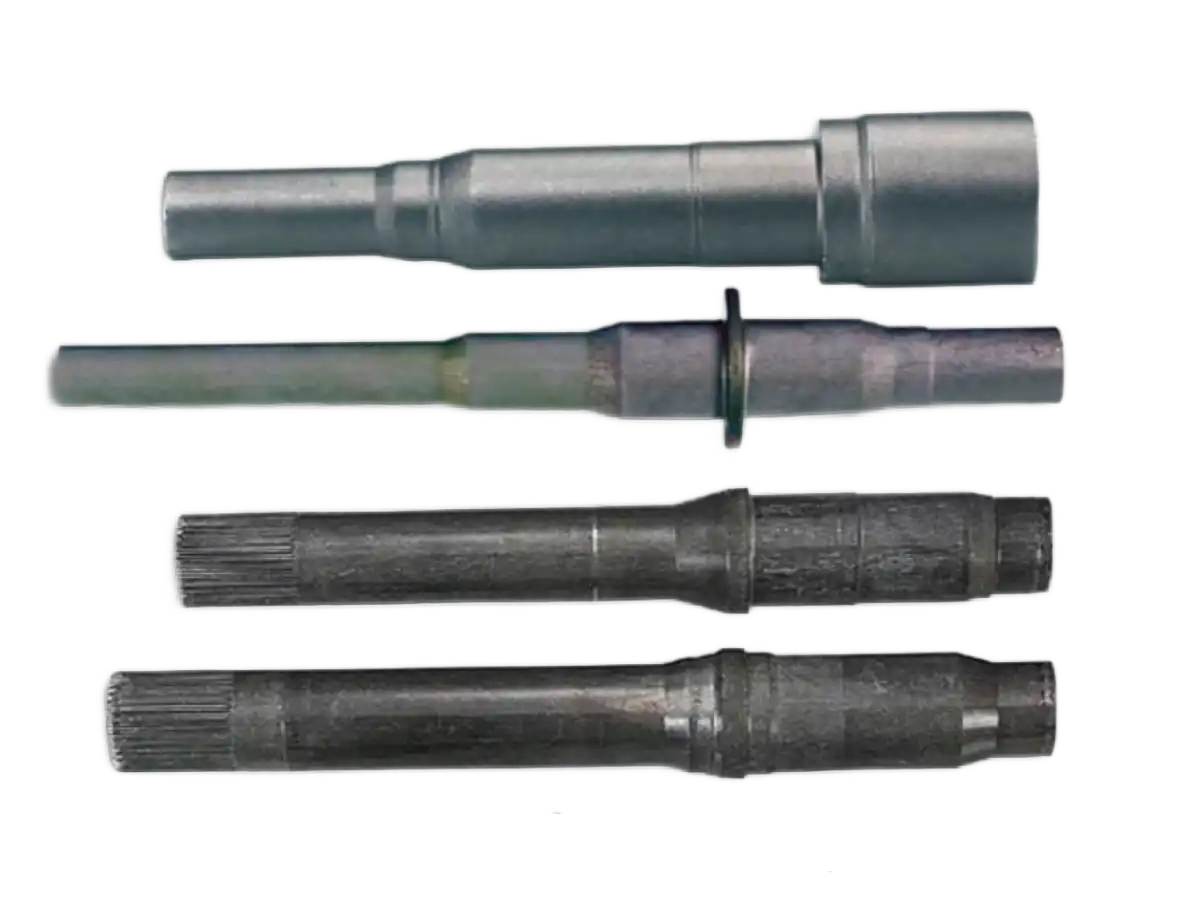

Sleever Driver

Cold Forged Transmission Shaft

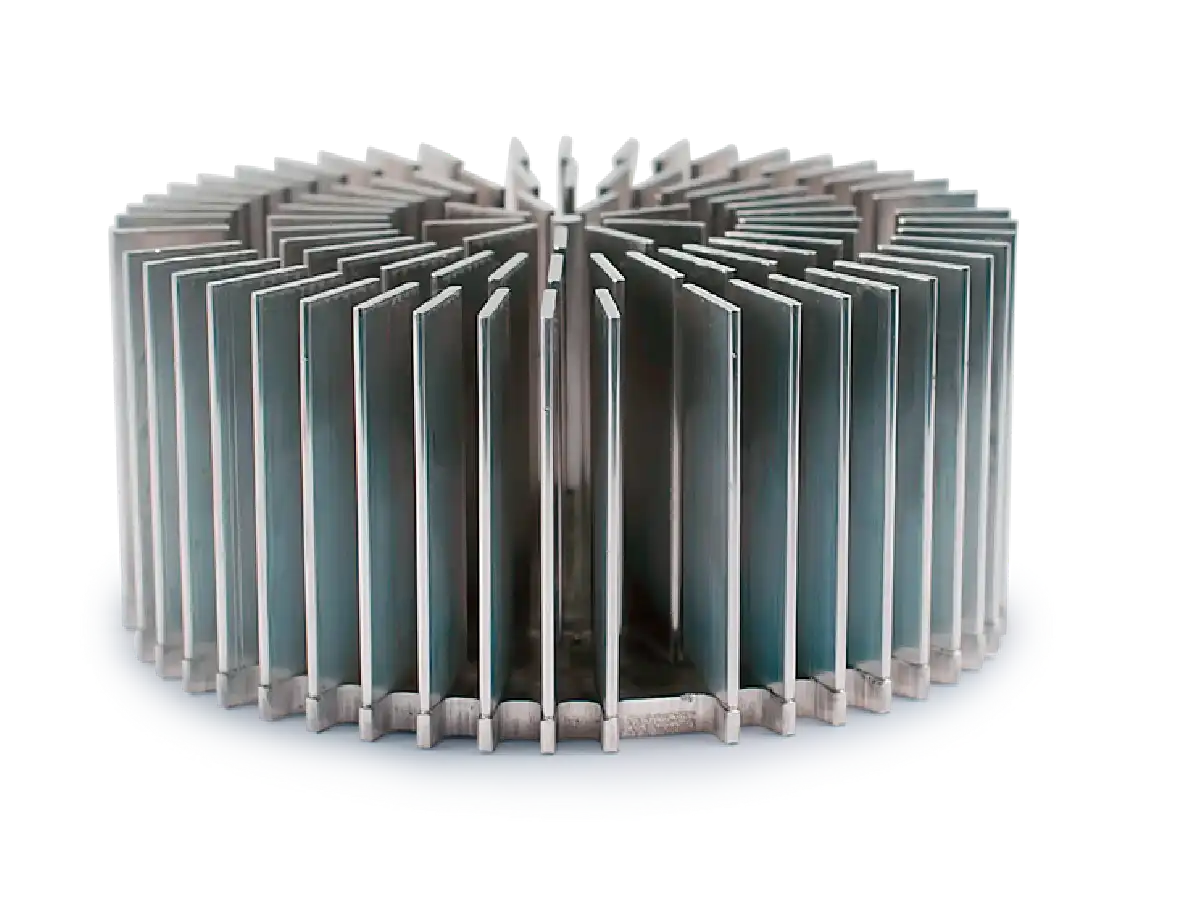

Heat Sink

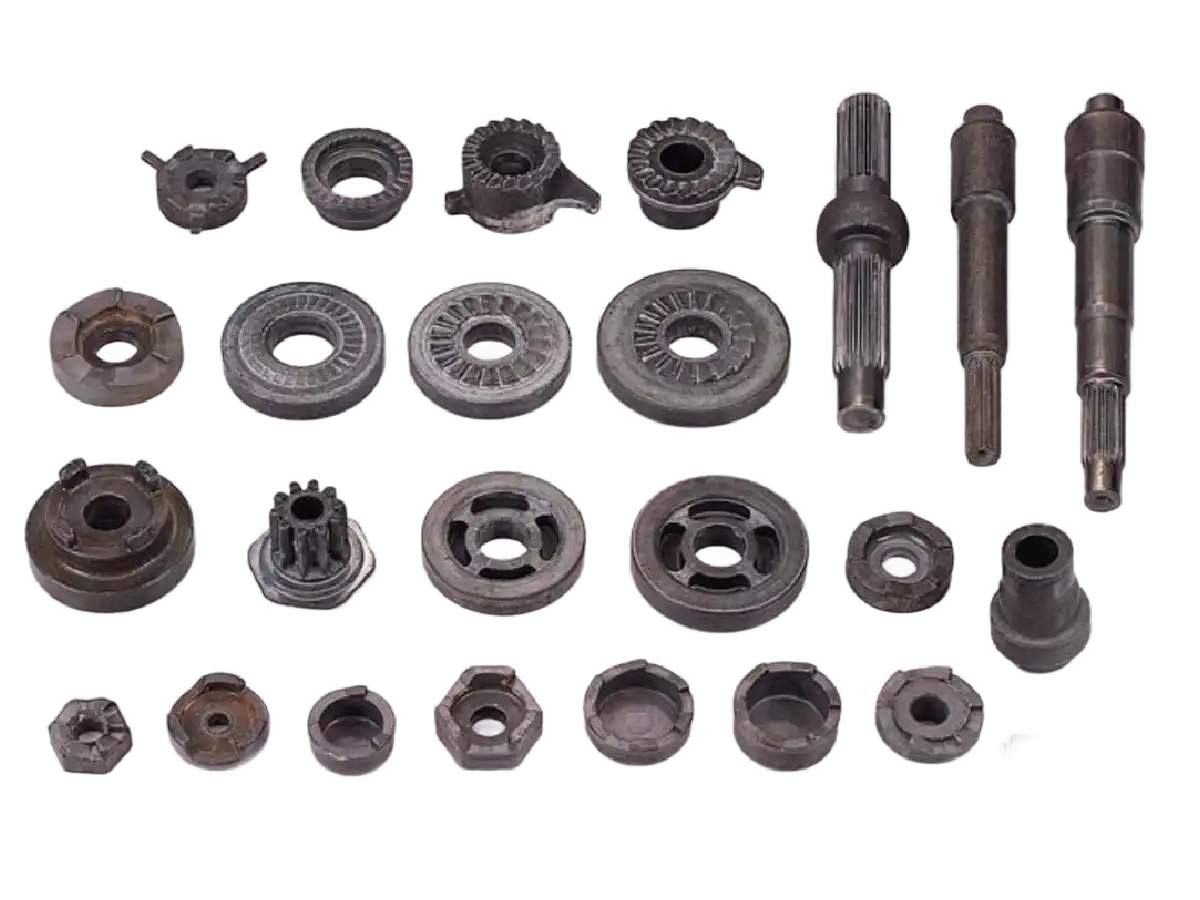

Cold Forged Assorted Components

Videos

What is Cold Forging?

Cold forging is a high-pressure metal forming process performed at or near room temperature. In this process, a metal billet is compressed within a die cavity using substantial force, causing it to plastically deform into the desired shape. Unlike hot forging, cold forging does not involve heating the billet, which results in superior surface finishes, enhanced material strength due to strain hardening, and tight dimensional tolerances.

Cold forging is widely used for high-volume production of components such as bolts, screws, rivets, gears, and structural automotive parts—where precision, repeatability, and material efficiency are critical.

Cold Forging Presses Built for Accuracy & Efficiency

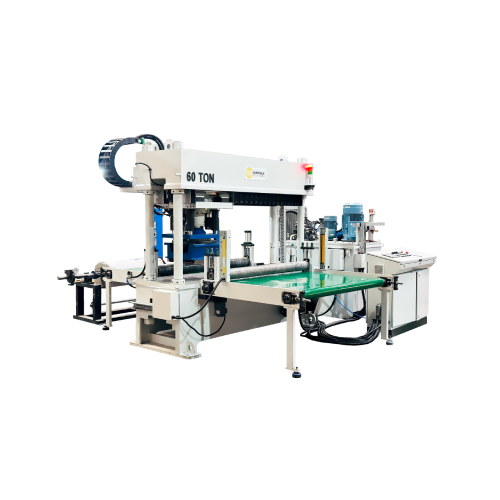

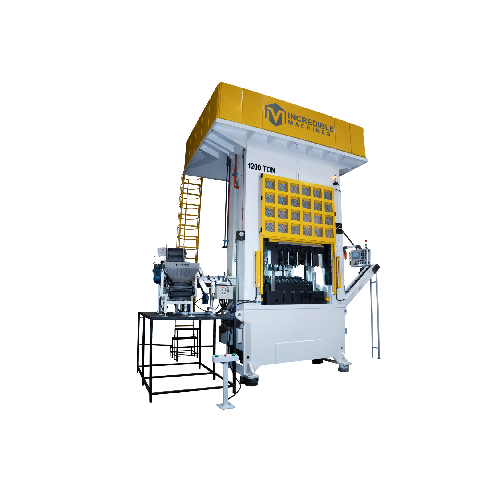

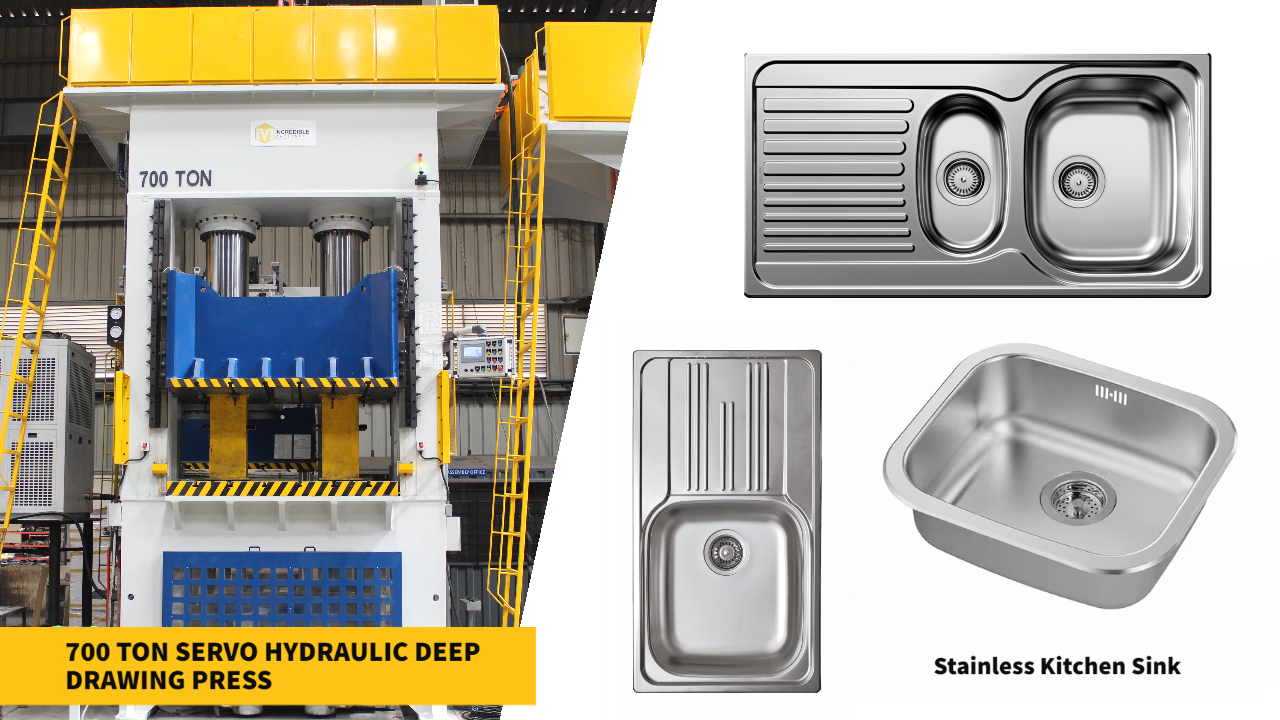

Our hydraulic cold forging presses are built to handle high-tonnage forming with unmatched accuracy and consistency. With capabilities ranging from compact units to ultra-heavy-duty presses, our solutions serve industries such as automotive, aerospace, industrial hardware, electronics, and tooling—where part consistency, surface finish, and production speed are paramount.

Key Features of Our Cold Forging Presses

- High-Rigidity Frame Structures: H-frame, 4-Column, or Monolithic options, designed for minimal deflection under high loads

- High-Precision Slide Guidance: Linear guide systems for excellent alignment and tool life

- Multi-Action Forging Capability: Optional lower/upper multi-platen motion for complex part geometries

- Energy-Efficient Hydraulic Systems: Direct drive or accumulator-based systems with optional servo-hydraulic upgrades

- Quick Die Change Systems: Reduce downtime during changeovers for high-mix production environments

- Servo-Controlled Stroke & Force Management: For precise and repeatable forming in critical applications

- Integrated Cooling Systems: Maintain thermal stability of tooling and improve dimensional accuracy

- Smart HMI Control Panel: User-friendly interface with programmable logic, diagnostics, and recipe management

- Production Monitoring: Real-time data acquisition and report generation for traceability and optimization

- Safety Systems: Light curtains, pressure relief, interlocks, and emergency stop features built to international standards

Applications of Our Cold Forging Presses

Our presses are suited for a wide variety of precision cold forming operations, including:

- Bolt & Fastener Forming

- Precision Shaft Forging

- Gear Blanks & Spline Shafts

- Automotive Suspension & Chassis Components

- Connector Pins, Rivets, and Studs

- Micro-Forging for Electronics & Medical Components

Custom Solutions Up to 3,000 Tons and Beyond

We understand that no two forging applications are the same. That’s why we offer fully customizable cold forging press solutions, with capacities ranging up to 3,000 tons and beyond. Our systems can be configured with:

- Hydraulic ejectors and knockout systems

- Die lubrication & pre-alignment units

- Robotic and manipulator integration

- Automatic die loading and storage systems

- Rotary index tables or sliding transfer units

- Integrated in-line inspection and gauging systems

Industries We Serve

- Automotive & Electric Vehicle (EV) Components

- Aerospace & Precision Engineering

- Hardware & Tooling

- Medical & Micro-Mechanical Parts

- Industrial Machinery & Power Transmission

Contact us today to discuss your cold forging needs or request a custom quote.