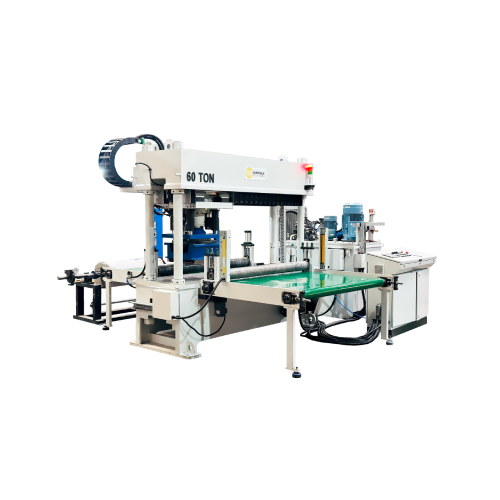

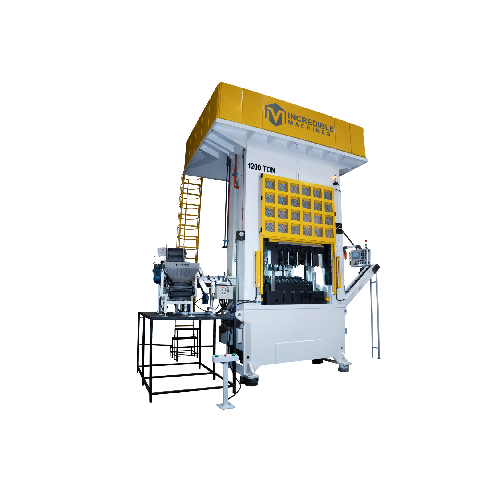

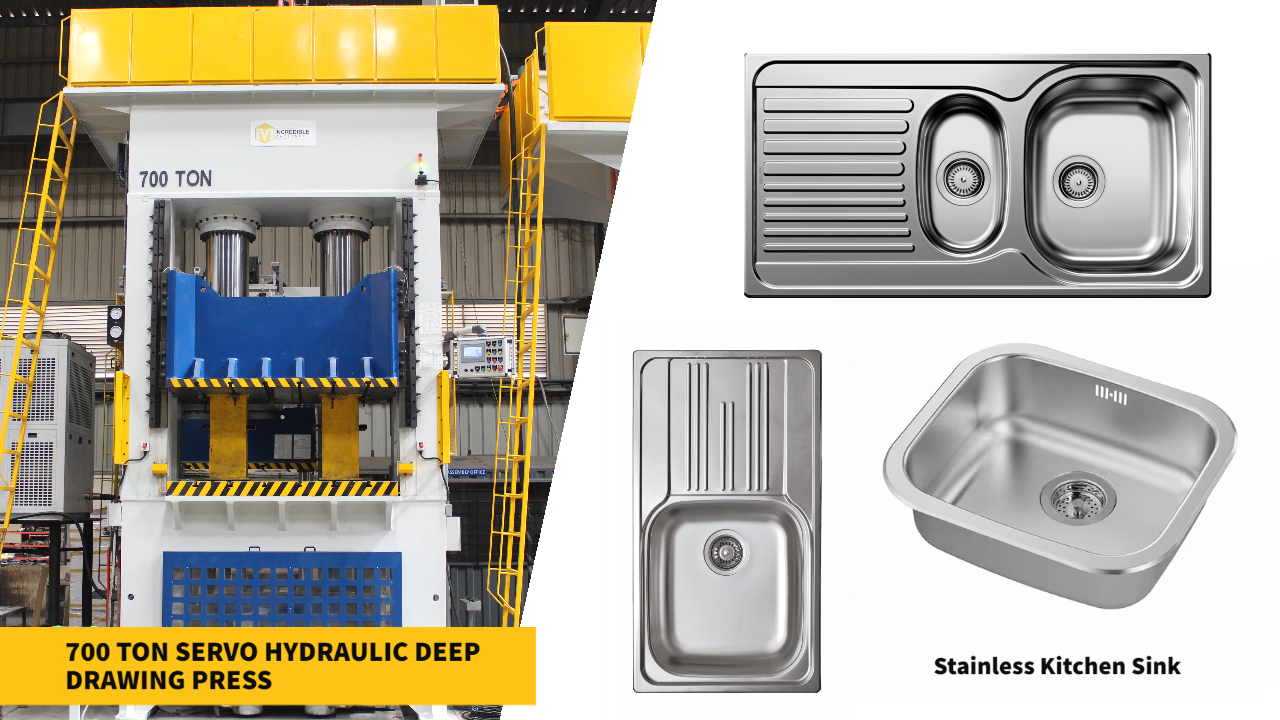

Thermoforming & Trim Presses for Automotive Interior Manufacturing

At Incredible Machines Pvt. Ltd., our advanced Thermoforming and Trim Presses are engineered to provide exceptional precision, repeatability, and operational flexibility, specifically tailored to meet the demands of modern automotive manufacturing. These presses are ideal for producing a diverse range of lightweight, durable, and intricately shaped components that contribute to both the functional integrity and aesthetic appeal of vehicle interiors and structural assemblies

Applications & Use Cases

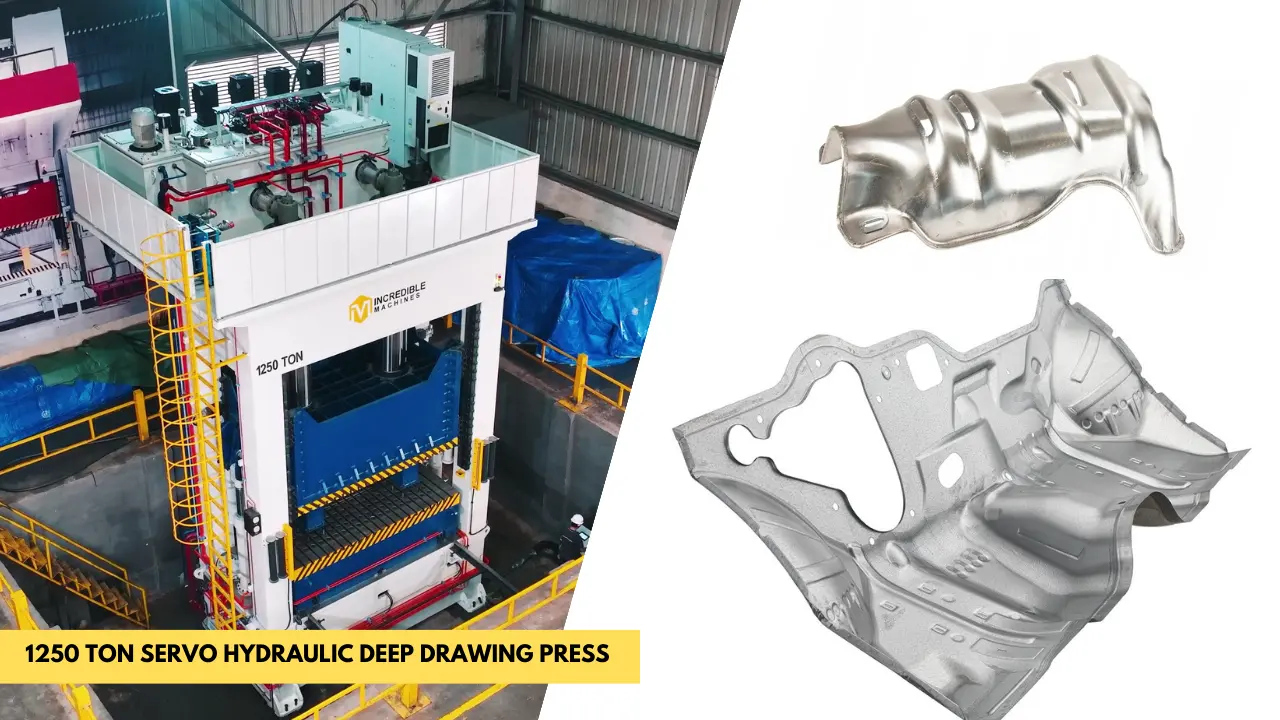

Automotive Components

Videos

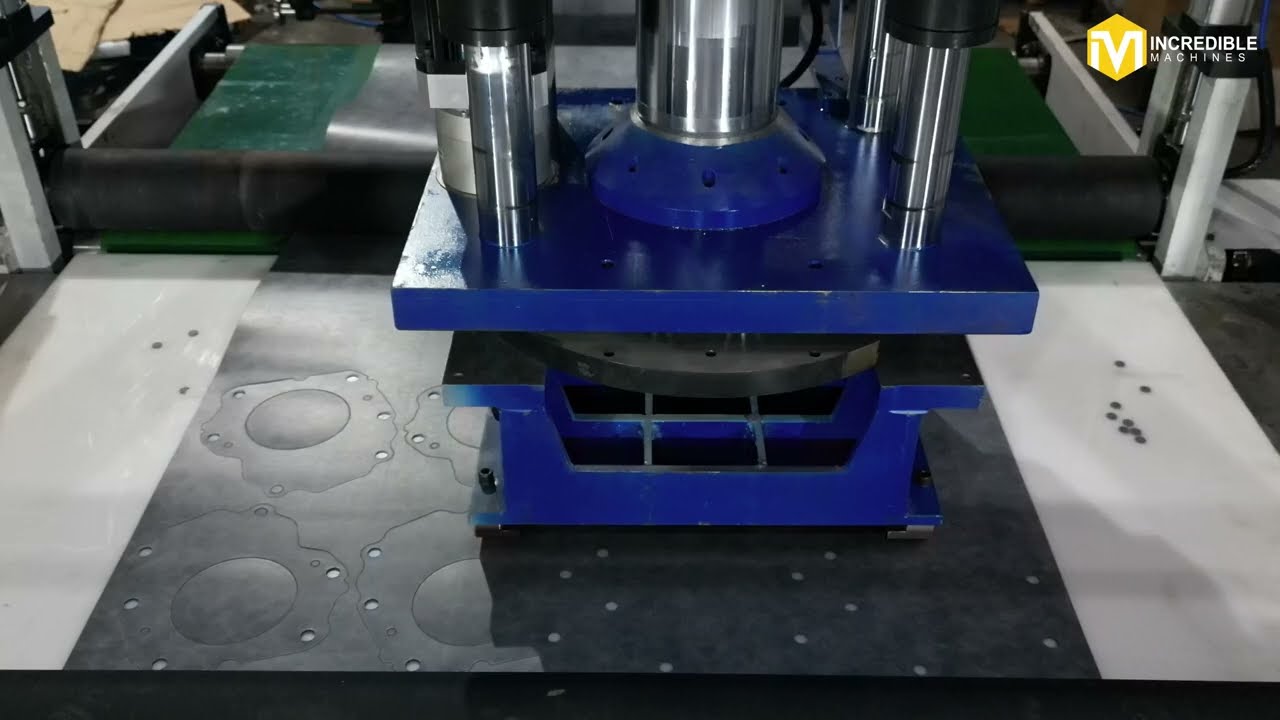

Applications in Automotive Manufacturing

Our thermoforming and trim presses are extensively utilized across the automotive industry for manufacturing:

- Instrument panels

- Door panels

- Parcel Trays

- Headliners, trunk liners, and hood liners

- Interior trims and insulation panels

- Rear deck covers and firewalls

- Foam insulators and NVH parts

- Trimming of precision metal components

These systems are engineered to meet diverse manufacturing demands while ensuring superior part aesthetics, long-term durability, and exceptional dimensional stability. The inherent versatility of our presses allows for seamless integration with custom toolsets, enabling rapid adaptation to evolving vehicle design requirements. In an industry defined by intense competition and the drive for efficiency, automotive manufacturers are constantly pursuing innovations to produce lighter, stronger, and more sustainable components. Thermoforming and trim presses are instrumental in facilitating this transformation, supporting the shift toward advanced materials and optimized part design.

Engineering the Press: Precision in Every Detail of Hydraulic Mould & Trim Presses: Features & Customization

Our Thermoforming and Trim Presses are engineered for customization, high performance, and long-term reliability. Each hydraulic moulding and trimming press is tailored to meet precise customer production requirements, and can be equipped with a range of optional advanced features, including:

- Robot arms or feeders

- In-die cooling/heating elements

- Quick-change tooling setups

- Electrically heated platens

- Vacuum systems with zone control

- Ejectors and integrated punches

- Moving bolsters for easy die handling

- Auxiliary hydraulic circuits for core pulls or eject functions

- Remote diagnostics and control packages

- Servo Based System for Energy Saving

The modular design allows for scalable upgrades, ensuring our presses remain future-proof amid shifting design and model refresh cycles in automotive platforms.

Built for Automotive Innovation

As automotive design cycles become faster and more intricate, the need for flexible, high-precision forming systems becomes critical. At Incredible Machines, our Thermoforming & Trim Presses are engineered not just for today's parts, but for tomorrow's innovations.

We invite you to explore how our custom-engineered hydraulic presses can elevate your production capabilities.

Let’s Build the Future of Mobility Together

Contact us to discuss your requirements or request a customized solution tailored to your pressroom and part