Precision Engineered Hydraulic Solutions for High-Performance Forging

At Incredible Machines Pvt. Ltd., we specialize in the design and manufacture of fully customized hydraulic hot forging presses, engineered to meet the most demanding forming requirements with exceptional strength, precision, and repeatability. Built to endure extreme temperatures, substantial loads, and off-center forging forces, our presses deliver reliable, high-performance results in even the most rigorous high-volume, high-precision forging operations.

Applications & Use Cases

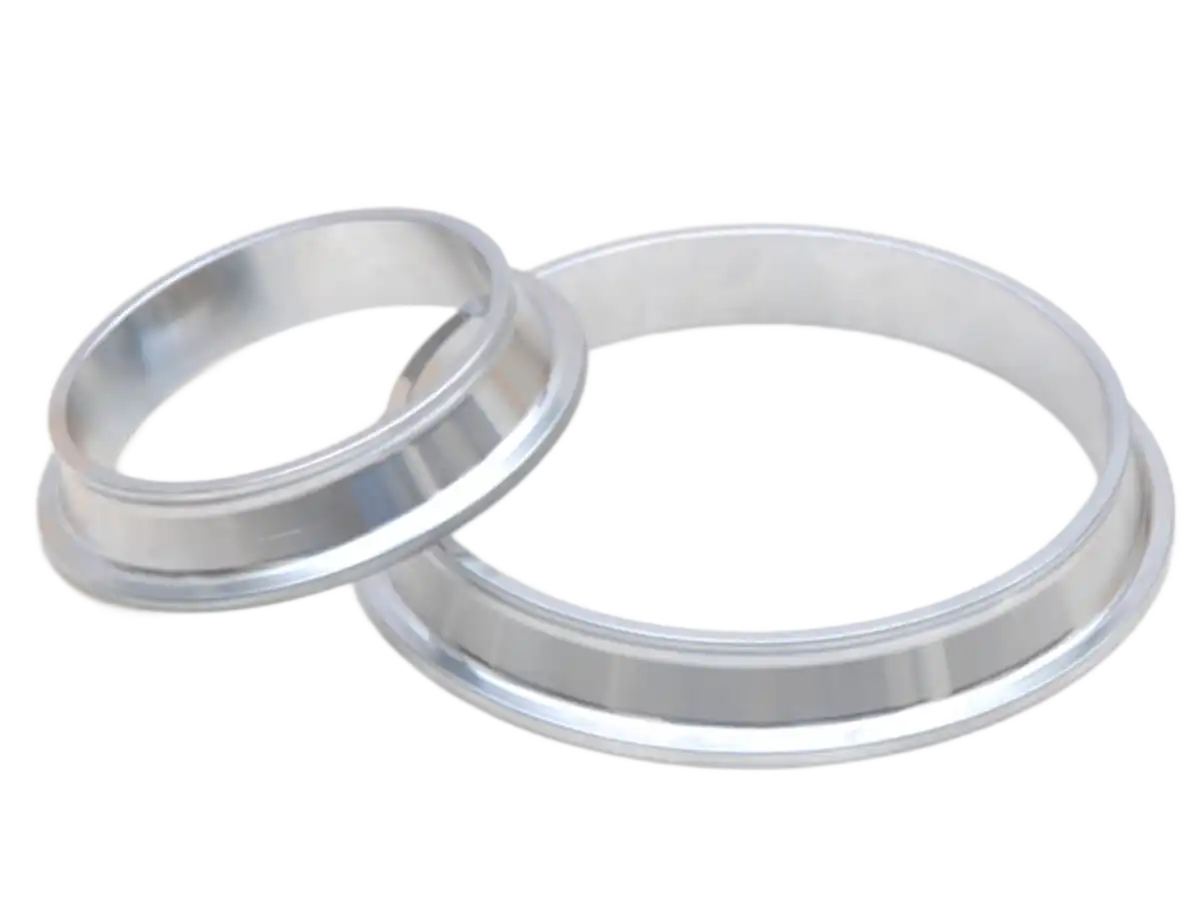

Bearing Case

Forged Rolled Ring

Titanium Alloy Fastners

Connecting Rod

Videos

What is Hot Forging?

Hot forging is a metal forming process in which a workpiece, commonly referred to as a billet, is heated to elevated temperatures, often reaching up to 1200°C, depending on the material. At these high temperatures, the billet becomes significantly more malleable, allowing it to be shaped under compressive forces through methods such as hammering, pressing, upsetting, or extrusion to achieve the desired geometry.

Compared to cold forging, hot forging enables the production of more complex part geometries, promotes superior material flow, and substantially reduces residual stresses. It is a highly efficient and cost-effective method for manufacturing high-strength components with minimal material waste.

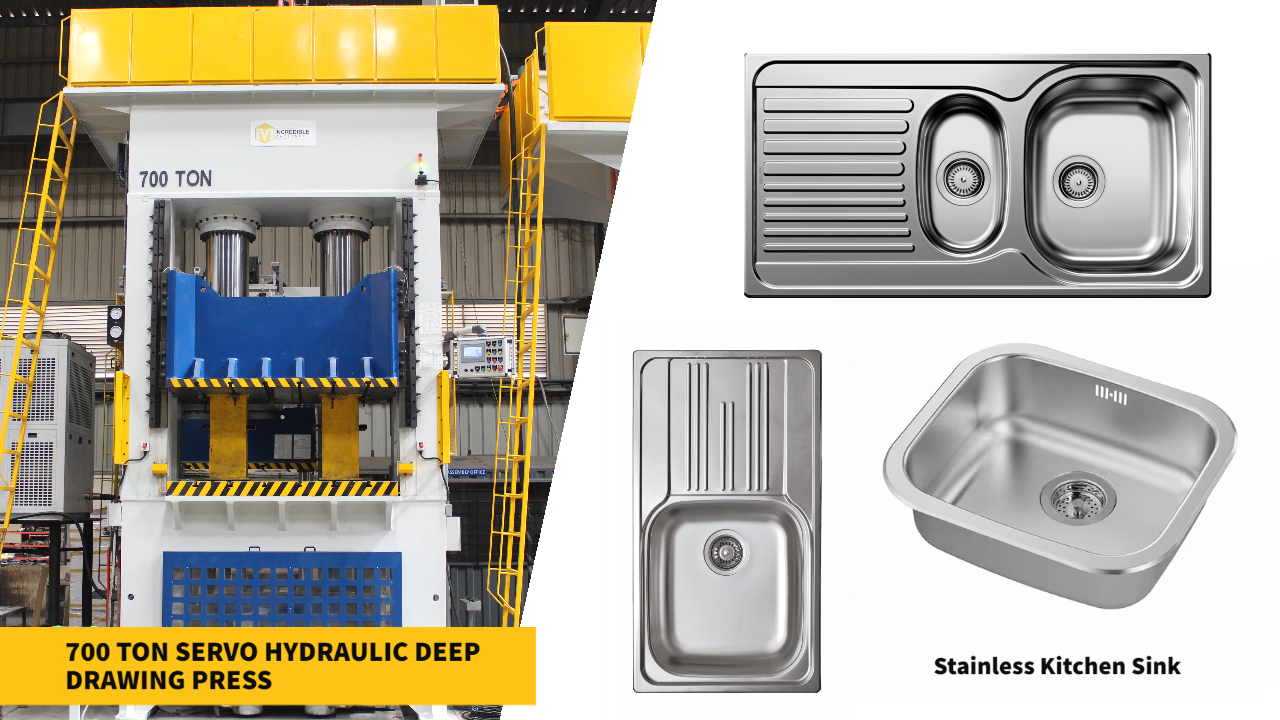

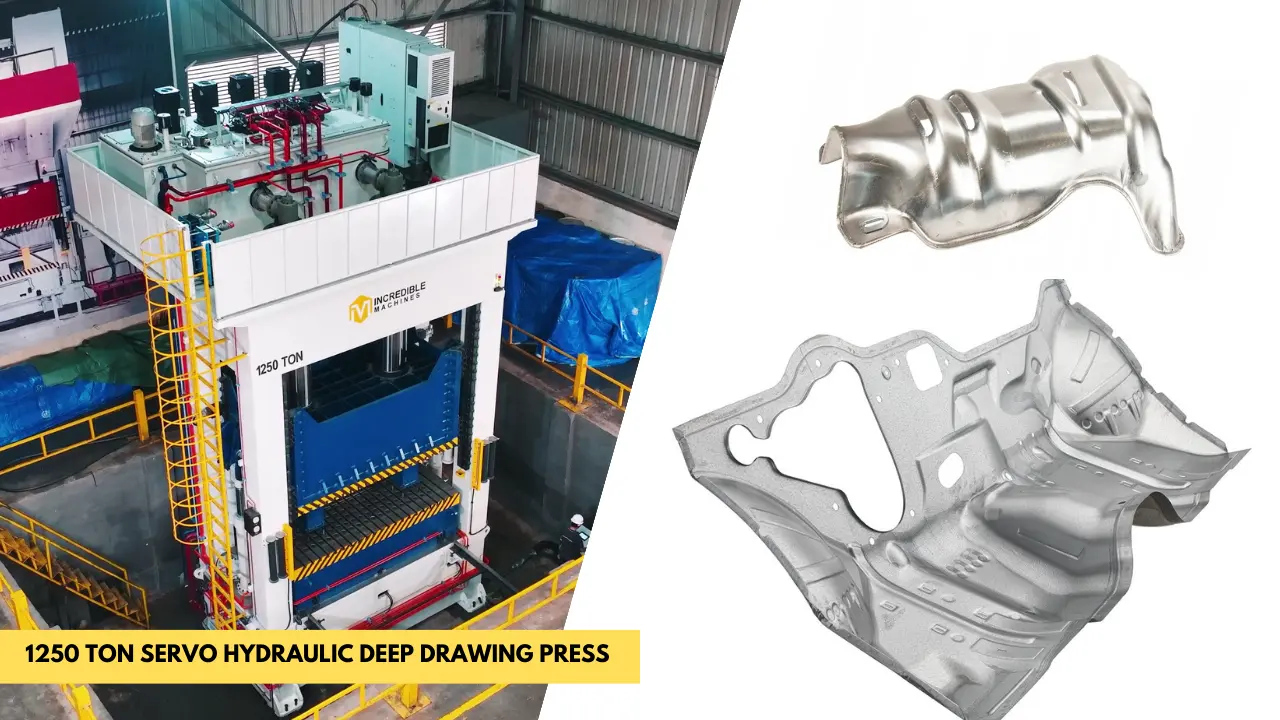

Hot Forging Presses Built for Productivity & Performance

We specialize in hydraulic hot forging presses engineered for consistent performance and precision in even the most demanding forging applications. Our presses serve a broad spectrum of industries—including automotive, aerospace, defence, earthmoving, and energy—where reliability, strength, and long-term durability are essential.

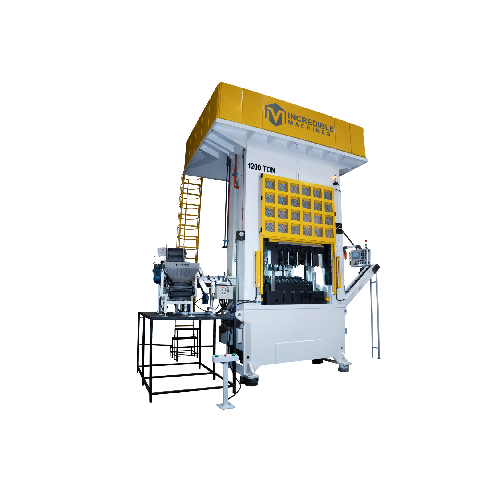

Key Features of Our Hot Forging Presses

- Heavy-Duty Frame Designs: Available in H-frame, 4-Pillar, and 4-Column configurations—engineered as per JIS 6403 grade accuracies to handle high forging forces with minimal deflection.

- Multi-Station Forging Capability: Enables sequential forging actions within a single cycle, improving throughput.

- Advanced Hydraulic Drives: Choose from direct or accumulator-based hydraulic systems, configured with high-speed actuation and energy efficiency.

- Servo-Based Operation: Precision-controlled stroke and force management for repeatable accuracy and power savings.

- Automated Production Systems: Includes auto-spraying for die lubrication, robotic loading/unloading, manipulators, and integrated transfer systems for seamless automation.

- Smart HMI Interface: Intuitive touch-screen controls for setting, storing, and managing process parameters with real-time diagnostics.

- Production Monitoring: Generate daily, weekly, and monthly reports with integrated data acquisition systems for better productivity insights.

- Auto-Lubrication Systems: Ensure smooth machine operation and longer component life.

- Comprehensive Safety Features: Safety curtains, interlocks, overload protection, and emergency stop systems built in for operator safety and system integrity.

Applications of Our Hot Forging Presses

Our hot forging systems are engineered for a broad spectrum of forging operations, including:

- Open-Die Forging

- Closed-Die Forging

- Upsetting and Cogging

- Solid Drawing & Extrusion

- Ring Blank Forging

- Piercing Operations

- Pre-forming for Ring Rolling

Custom Solutions Available up to 5,000 Tons and Beyond

Every forging application has its own unique requirements—that’s why we offer fully customized solutions. Our hot forging presses are available in a wide range of capacities, from medium to ultra-heavy-duty, including models up to 5000 tons and beyond.

- To enhance performance and versatility, these presses can be equipped with: Hydraulic ejectors & knock-out systems

- Die clamping and shuttle arrangements

- Quick die change packages

- Induction heating systems or ovens

- Rotary/sliding tables, conveyors, and robotic integration

- Automatic die storage & retrieval systems

Industries We Serve

- Automotive & Body-in-White (BIW) Components

- Heavy Industrial & Earthmoving Equipment

- Aerospace & Defence

- Energy Sector (Oil & Gas, Power Generation)

- Railway & Infrastructure Hardware

Partner with Us for Forging Excellence

With extensive industry experience and a proven track record in automation and system integration, Incredible Machines Pvt. Ltd. is a trusted partner in forging technology. From standalone presses to fully automated hot forging lines, we deliver end-to-end solutions designed to enhance uptime, minimize waste, and boost overall operational efficiency.

Contact us today to discuss your hot forging needs or request a custom quote for a turnkey system