Precision-Engineered Solutions for Mould and Tool Validation

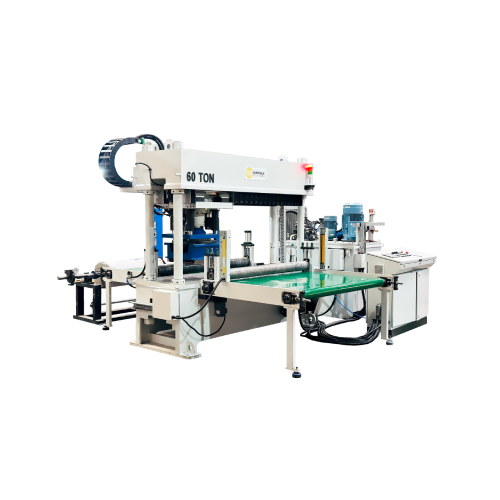

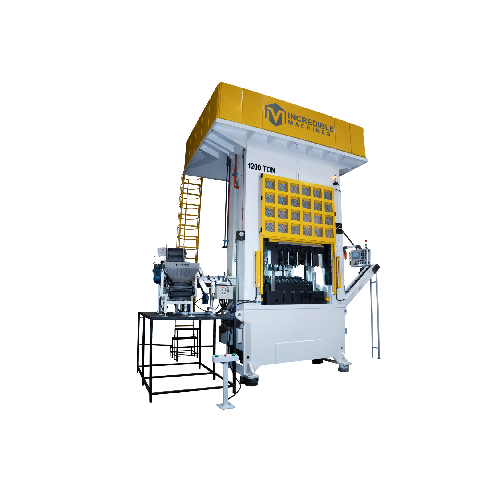

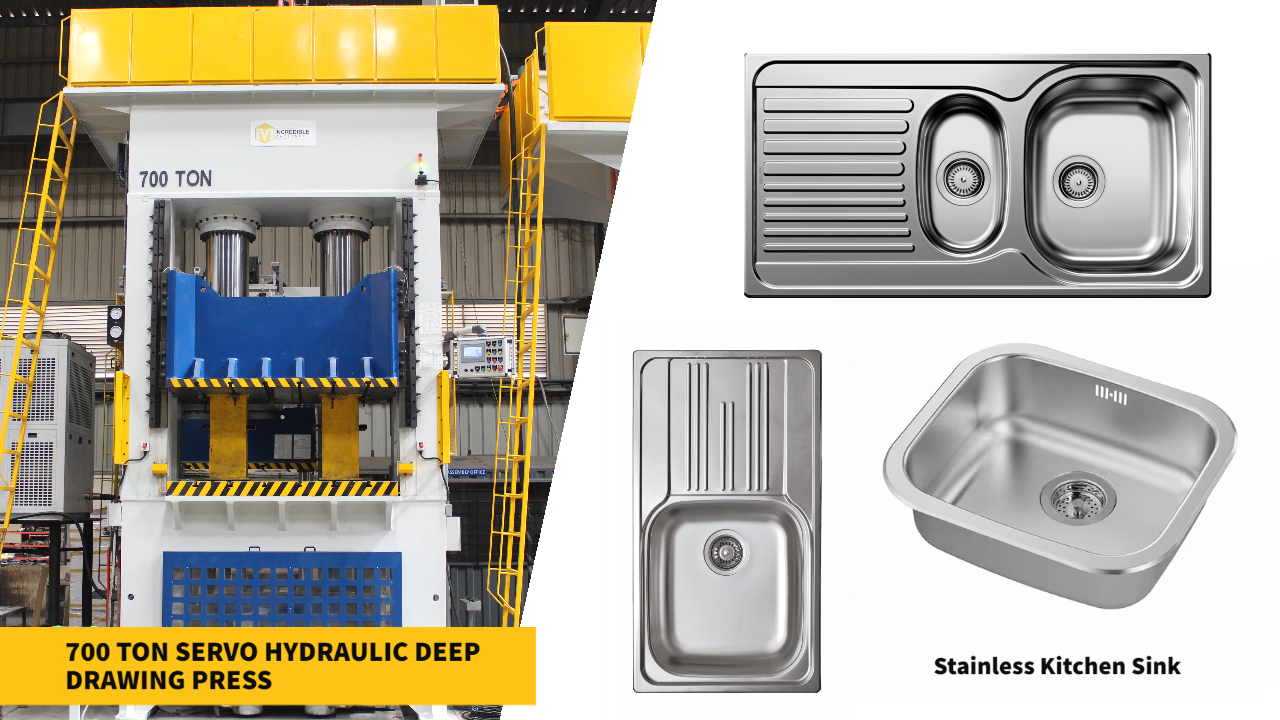

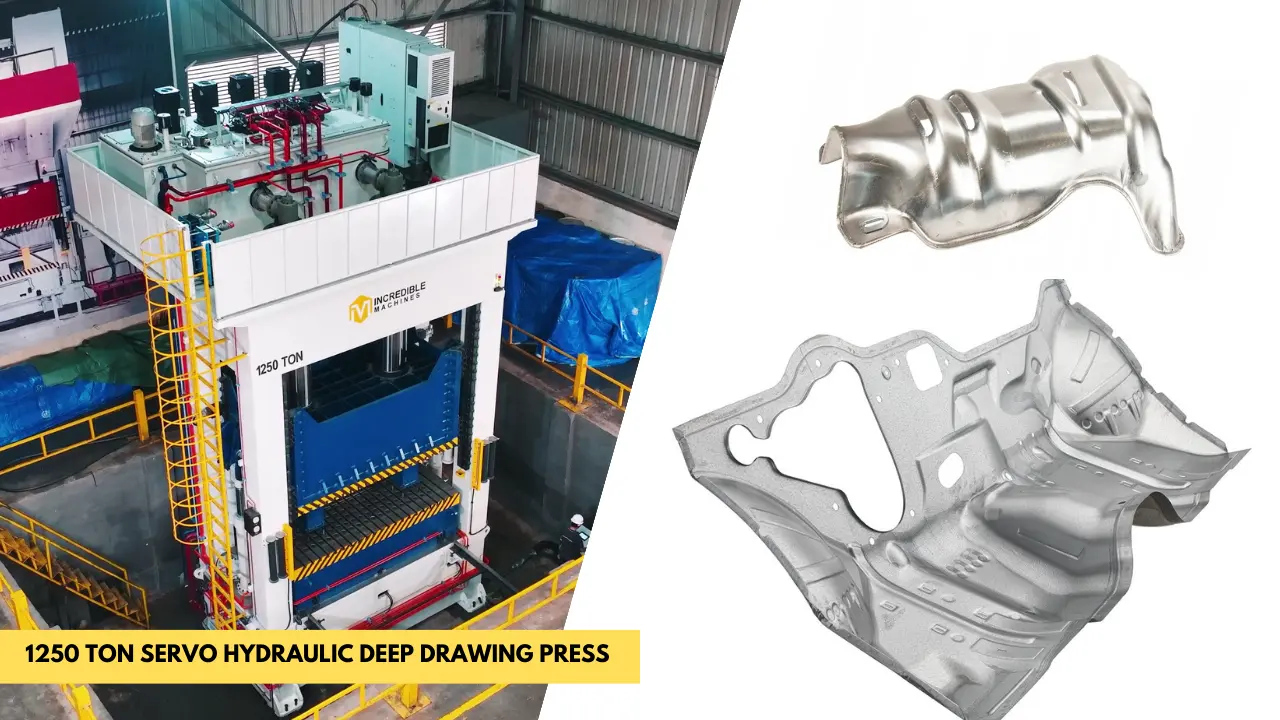

At Incredible Machines Pvt Ltd, we design and manufacture advanced hydraulic Die Spotting and Try-Out Presses, tailored to meet the exacting demands of today’s advanced tool rooms. Engineered for both metal forming and plastic moulding industries, our presses offer exceptional accuracy, repeatability, and reliability. Ideal for die validation, fine-tuning, and pre-production trials, they are capable of precisely simulating full-scale production conditions, ensuring seamless transitions from design to manufacturing

Applications & Use Cases

Component Inspection

Why Die Spotting & Try-Out Presses Are Critical

The process of die spotting and try-out is crucial in tool and mould making. These presses allow manufacturers to:

- Accurately match the upper and lower die or mould halves

- Check for surface contact accuracy and eliminate gaps

- Validate part geometries before moving to full-scale production

- Simulate real production conditions during mould testing

- Reduce costly errors and increase production uptime

Our presses ensure you detect and resolve any tooling imperfections at the pre-production stage, preventing downstream issues on high-value production presses.

Custom-Designed for Precision Spotting and Try-Out Applications

Every Die Spotting and Try-Out Press from Incredible Machines is custom-built to meet your unique tooling validation needs. Offered in a variety of tonnages, frame configurations, and equipped with modular automation options, our presses are engineered for optimal performance, whether in manual setups or fully automated tool rooms.

Key Features:

- 180° Rotating Platens: Allows ergonomic access and visual inspection of tool faces for spotting and polishing tasks.

- Tilting Platens: Enables better visibility and access for tool fitting, allowing improved manual finishing work.

- Rolling Bolsters: Streamlines die handling and die exchange, increasing overall efficiency and operator safety.

- Automatic Die Clamping and Lifting Systems: Reduces manual effort, enhances repeatability, and supports high-frequency tool changes.

- Servo-Controlled Slide Parallelism System: Ensures consistent slide movement and platen parallelism, critical for high-accuracy mould matching.

- Oversized Guide Components and High Depth-to-Span Ratios: Guarantees structural stiffness, superior alignment, and low deflection under load, resulting in excellent contact uniformity.

Simulate Full-Scale Production with Precision

Unlike conventional try-out presses, our machines are designed to replicate real-world production conditions with precision. This allows toolmakers and manufacturers to test dies and moulds under authentic pressures, speeds, and motion profiles, ensuring that every forming or moulding variable is thoroughly validated before full-scale production.

Our proprietary control systems are designed to:

- Mimic stroke curves and force profiles of production presses

- Allow easy adjustments to slide speed, pressure, dwell, and return

- Log performance data for analysis and optimization

- Store multiple tool programs and test cycles

This advanced simulation capability eliminates guesswork, shortens setup times, and allows users to optimize tooling for production, without occupying valuable time or resources on actual production lines.

Built for Performance, Ready for Production

One of the standout features of our Try-Out Presses is their exceptional versatility. While primarily designed for tool try-out and die validation, they are built with the same high standards of durability, precision, and engineering excellence as our full-scale production presses. This robust construction makes them equally well-suited for:

- Low-volume production runs

- JIT (Just-in-Time) manufacturing

- Emergency production scenarios

- Short-run or prototype part production

The ability to seamlessly transition from tool testing to full production mode, without compromising performance, greatly enhances your operational flexibility and maximizes return on investment.

Optimizing Tool Rooms & Mould Shops Across Industries

Our Die Spotting and Try-Out Presses are trusted in a wide array of industries including:

- Automotive Tooling & Dies

- Plastic Injection & Compression Moulds

- Sheet Metal Stamping Tools

- Appliance & White Goods Tooling

- Progressive Die & Transfer Tool Validation

- High-Precision Mould & Die Shops

Whether you're preparing a deep draw tool, a multi-cavity injection mould, or a progressive stamping die, our presses are engineered to handle the most demanding try-out challenges with unwavering precision and control.

Faster Turnaround. Higher Tooling Accuracy. Lower Cost.

By incorporating an Incredible Machines Try-Out or Die Spotting Press into your workflow, you gain:

- Reduced mould and die try-out time

- Increased uptime on production presses

- Enhanced tool accuracy and contact surface optimization

- Improved tool life due to accurate spotting

- Faster tooling turnaround for short-run production

- Reduced scrap and improved first-hit success rate

These advantages are especially critical in today’s fast-paced manufacturing environments, where tight timelines, high-mix/low-volume production, and zero-defect expectations are the norm.

Why Choose Incredible Machines?

- Custom-built presses tailored to your tooling requirements

- Robust engineering based on global standards and heavy-duty press design experience

- Advanced control systems with intuitive HMI interfaces and real-time diagnostics

- Safety-first design philosophy with all required guarding, interlocks, and operator protection

- End-to-end support from design and commissioning to service and upgrades

- In-house automation integration including die handling, clamping, and robotic support

Let’s Validate Your Tools with Confidence

Whether you're a toolmaker in need of high-precision spotting or a manufacturer looking for faster turnaround with production-level accuracy, our Die Spotting and Try-Out Presses deliver exactly what your operation requires.

Talk to our technical team today to explore your tooling needs and get a custom-engineered press solution tailored to your workflow, budget, and performance goals.