High-Performance Metal Forming Presses for Industrial Manufacturing

At Incredible Machines Pvt. Ltd., our Hydraulic Metal forming Presses are purpose-engineered for high-performance production environments across a wide spectrum of metalworking industries. Engineered with robust construction, precision guidance systems, and an extensive list of performance-enhancing features, our presses are designed to deliver maximum forming force, consistent repeatability, and long-term durability, even under the most demanding operational conditions.

Applications & Use Cases

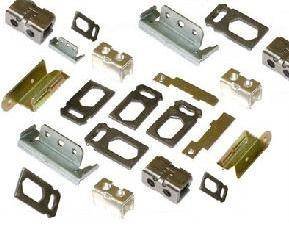

Sheet Metal Components

Videos

Engineered for Strength, Precision, and Endurance

Our metal forming presses are designed with heavy-duty welded frames and deep fabricated slides, purpose-built to withstand high eccentric loading while ensuring long-term structural integrity. A key design advantage lies in the use of high slide guide ratios, which provide:

- Exceptional parallel slide motion

- Reliable guiding precision under off-center or unbalanced loads

- Enhanced die alignment and improved part dimensional accuracy

Whether you're operating with complex tooling configurations or forming large metal components, our presses can be supplied with custom or standard T-slot layouts or tapped hole patterns on both the bolster and slide—ensuring seamless integration with your specific dies and fixtures.

Low-Headroom Press Design for Space-Constrained Facilities

Recognizing the challenges faced in plants with limited vertical clearance or pit depth constraints, we offer an innovative low-headroom press configuration. By mounting the hydraulic power unit (HPU) at the rear of the press, we eliminate the need for deep foundation pits or floor-mounted hydraulic systems. This not only reduces the overall machine height but also:

- Minimizes installation complexity

- Optimizes factory floor space

- Enhances maintenance accessibility

This feature is especially valuable for manufacturers retrofitting existing production floors or working within space-limited environments

Comprehensive Options to Enhance Capability & Customization

To address the diverse requirements of modern metal forming operations, our presses can be configured with a comprehensive range of optional systems and features, each designed to enhance performance, improve safety, and minimize operational downtime. These include:

- Hydraulic cushions (single-point or multi-point) for deep draw applications

- Light curtains and laser scanners for operator safety

- Fixed or motorized sliding safety doors

- Integrated LED work lighting for improved visibility

- Remote diagnostics and monitoring packages

- Blank holder/punch holder systems

- Automatic centralized grease lubrication systems

- Slide locking systems (manual or programmable multi-position locking)

- Quick die change systems including die lifters and hydraulic/manual die clamping

- Integrated data acquisition and part quality monitoring systems

Each of these features can be tailored to your specific production goals—whether you're prioritizing speed, flexibility, ease of maintenance, or real-time process monitoring.

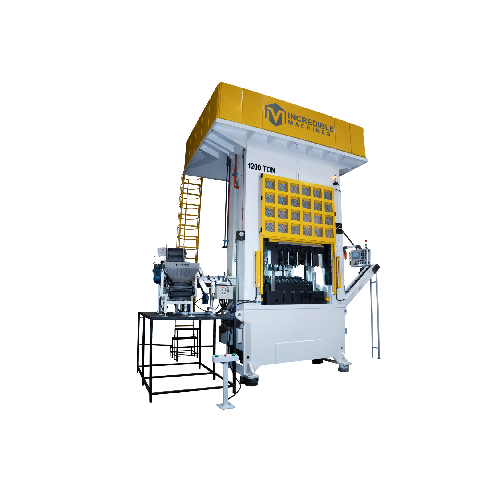

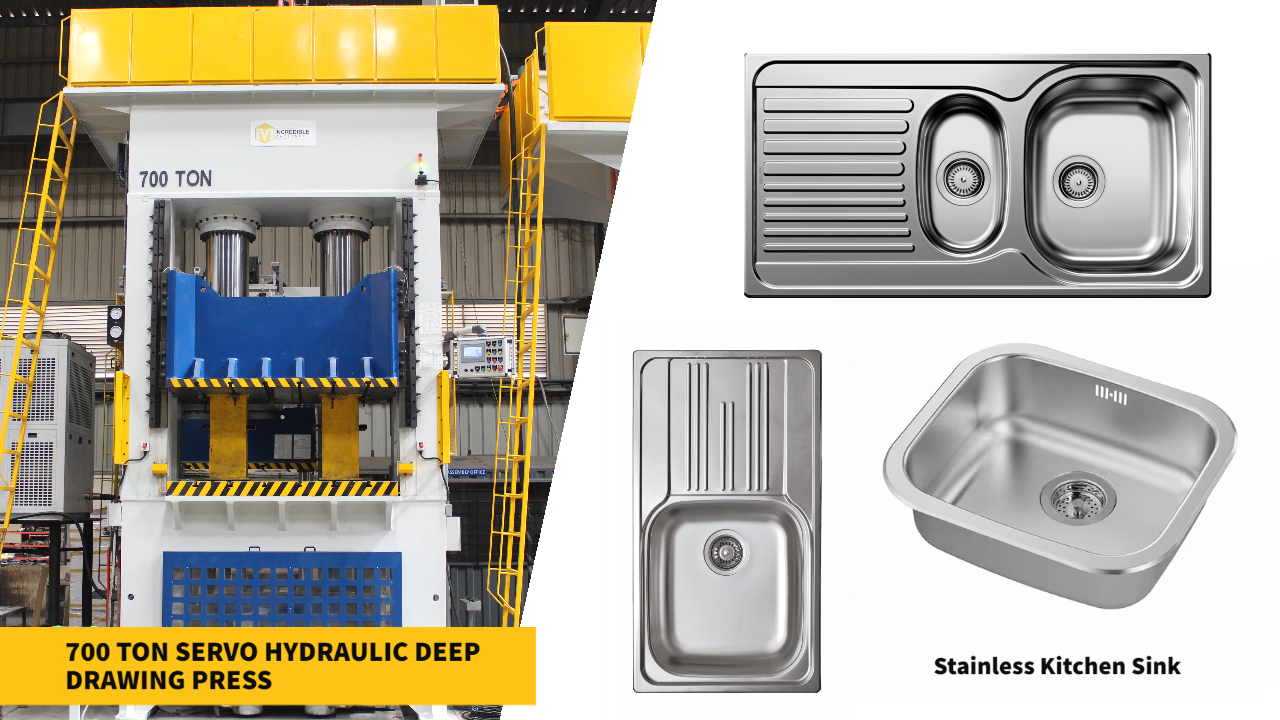

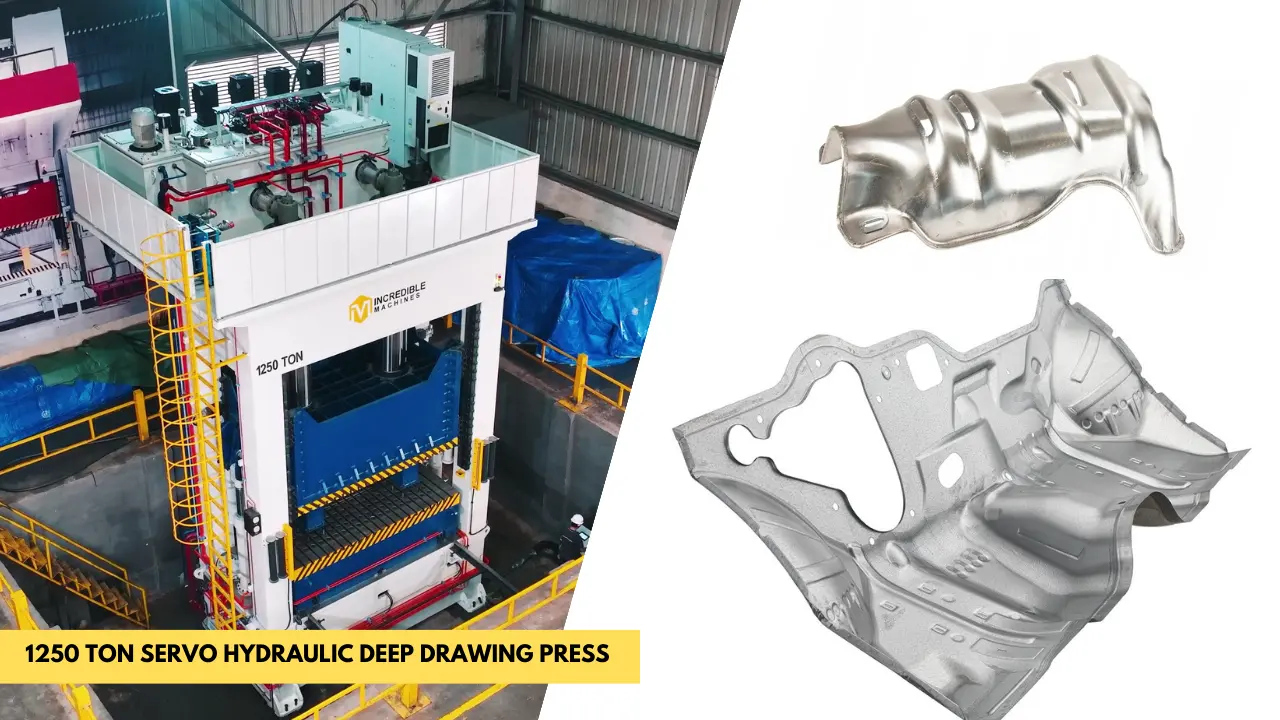

Servo-Hydraulic Press Technology: The Best of Both Worlds

For manufacturers looking to combine the raw power of hydraulics with the precision and energy efficiency of servo-driven systems, our presses can be optionally upgraded to Servo-Hydraulic technology. This upgrade provides:

- Fully programmable ram motion profiles

- High-speed approach and return strokes

- Ultra-precise dwell and forming speeds

- Lower energy consumption through smart motion control

- Reduced heat generation and hydraulic wear

This integration allows your metal forming press to dynamically adapt to varying materials and tooling configurations, delivering exceptional process control, repeatable accuracy, and cost-efficient performance, whether in low-volume prototyping or high-volume production runs.

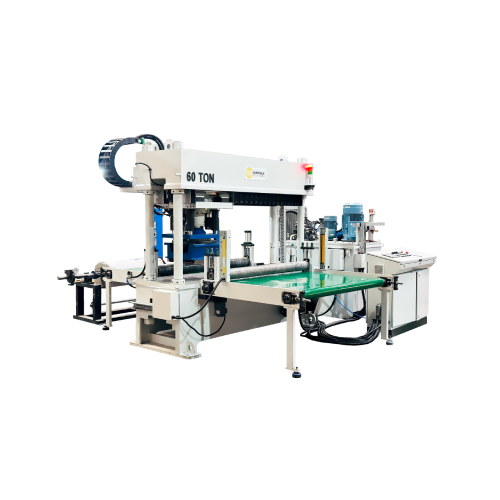

Automated Metal forming Systems for Higher Productivity

Our presses are not just standalone machines—they are also designed to seamlessly integrate into automated press lines or manufacturing cells. Depending on your production setup, we offer:

- Turnkey automated systems including coil feeders, transfer systems, stacking units, and robotic handling

- Partial automation solutions, where we integrate with buyer-supplied automation and equipment

- Press control interfaces with communication protocols for smooth coordination with ancillary devices

With extensive system integration experience, our team works closely with you to design and implement custom automation solutions—ensuring synchronized operation, faster changeovers, and optimized material flow.

Whether you’re automating a single workstation or transforming an entire line, our solutions are designed for maximum efficiency, without compromising on budget or performance.

Ideal for a Range of Metal forming Applications

Our hydraulic metal forming presses are suitable for a wide range of forming processes, including but not limited to:

- Deep drawing

- Blanking and punching

- Coining

- Embossing

- Forming of high-strength and multi-layer metals

- Complex part shaping for automotive, appliance, aerospace, and general metal fabrication industries

Why Choose Incredible Machines Metal forming Presses?

- Heavy-Duty Frame Construction for long-lasting reliability

- High Guide Ratios for parallel and stable slide movement

- Customizable Tooling Interface to match existing dies and fixtures

- Compact Low Headroom Design for floor space optimization

- Servo-Hydraulic Options for energy-efficient precision forming

- Safety and Automation Ready for modern manufacturing environments

- Custom Automation Integration for scalable productivity

Contact us today to consult with our engineering team or request a custom quote for your metal forming application.