Air Conditioner Outdoor Unit Casings

Deep Drawn for Strength, Fit & Aesthetics

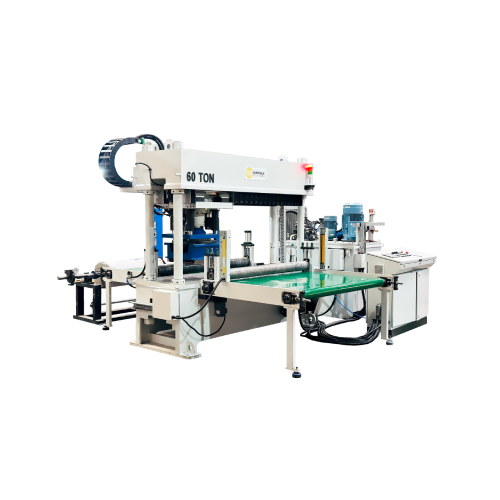

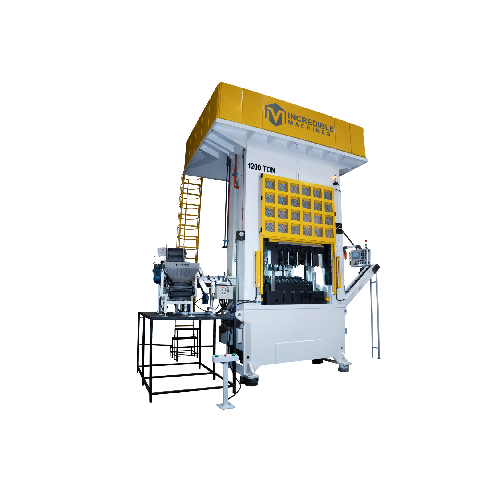

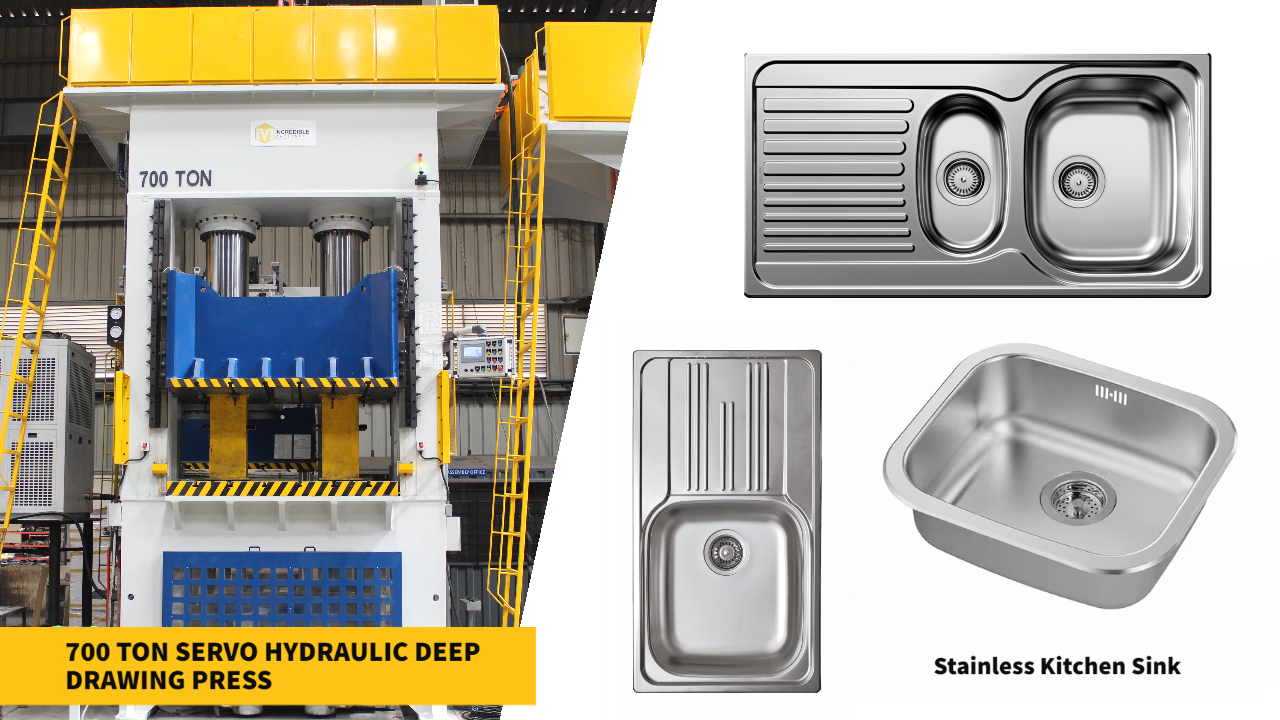

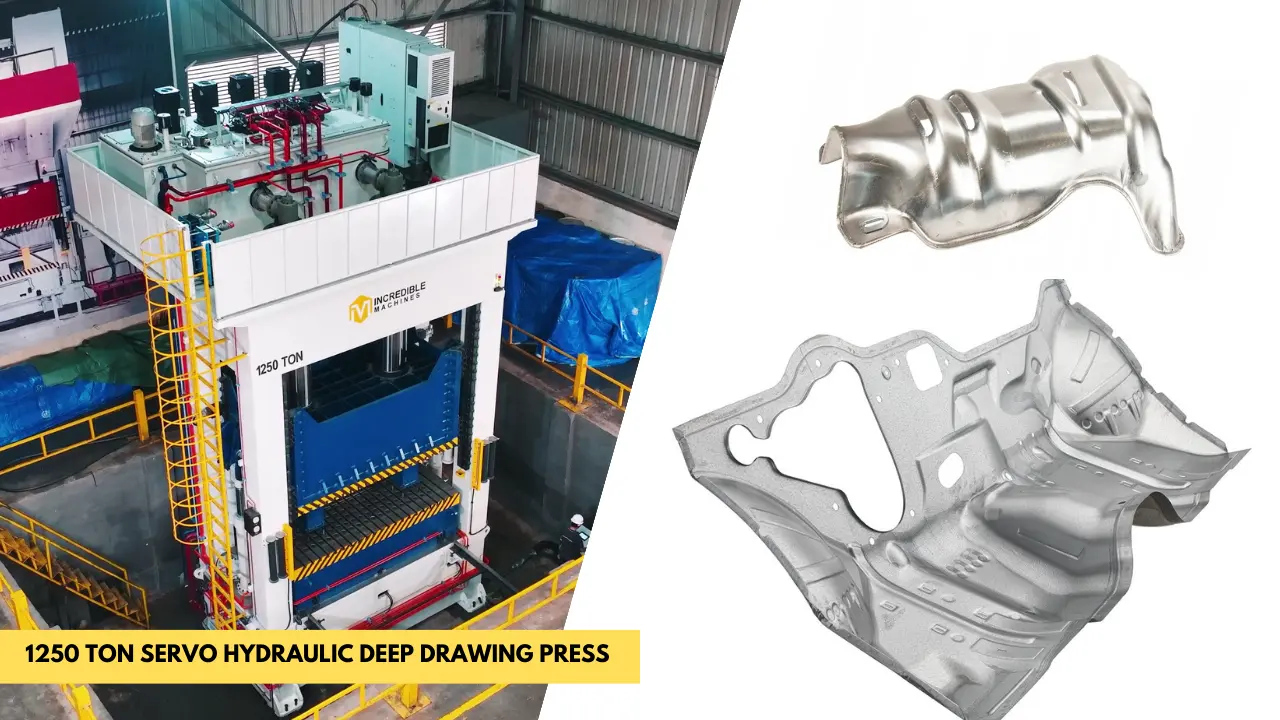

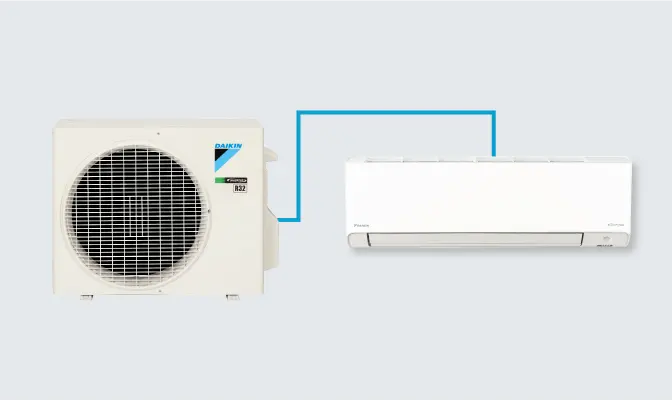

The metal enclosures featured here are AC outdoor unit casings, typically made from pre-coated or galvanized steel sheets. These parts are manufactured using a hydraulic deep drawing process to meet the critical requirements of modern air conditioning systems.

Condenser Covers / Outer Casings

Used in split air conditioners and commercial HVAC systems, these housings protect internal components like compressors, coils, and fans from dust, water, and physical damage — while ensuring optimal airflow and heat dissipation.

Applications & Use Cases

Air Conditioners

Videos

Why Deep Drawing is Ideal for These Parts:

- Forms large, box-type shells in a single stroke, reducing part joints and welding

- Maintains uniform wall thickness with clean edges and corners

- Offers high structural strength while using lightweight metal sheets

- Enables aesthetically clean surfaces for painting or powder coating

- Supports mass production with consistent dimensional repeatability

Applications:

- Residential and Commercial Air Conditioners – Wall-mounted, floor-standing, or cassette-type outdoor units

- Refrigeration & Heat Pump Units – Outdoor shell for thermal management equipment

- HVAC Enclosures – Custom casings for environmental control and protection

Functional Requirements Met by the Process:

- Weather resistance

- Rust-proof finishing compatibility

- Easy assembly with bolt-and-fit alignment

- Noise isolation and fan cutout accuracy

- Compliance with OEM standards for external mounting

Precision Drawn Enclosures for Climate Control Systems

With the growing demand for energy-efficient air conditioning systems, deep drawn metal casings offer a perfect blend of functionality, strength, and aesthetics. They’re produced with high accuracy to ensure perfect fitting, protection, and durability in real-world usage.