Automotive Fuel Tanks – Manufactured with Precision Hydraulic Presses

Automotive fuel tanks are critical components designed to safely store and deliver fuel to a vehicle's engine. Whether made from steel, aluminum, or advanced composites, these tanks must meet strict safety, durability, and dimensional accuracy standards.

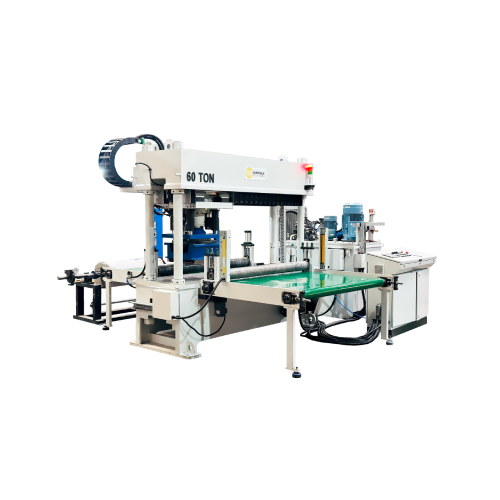

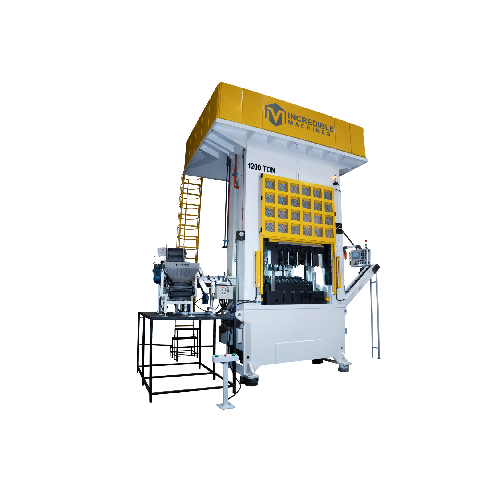

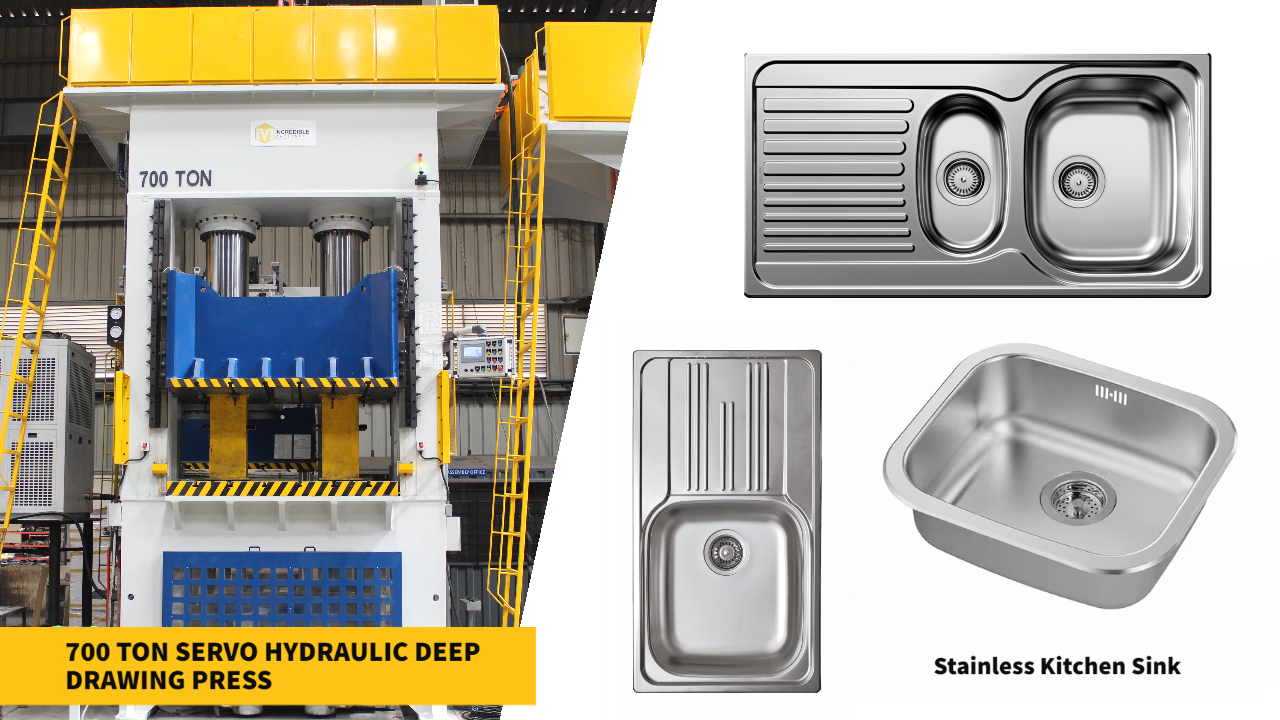

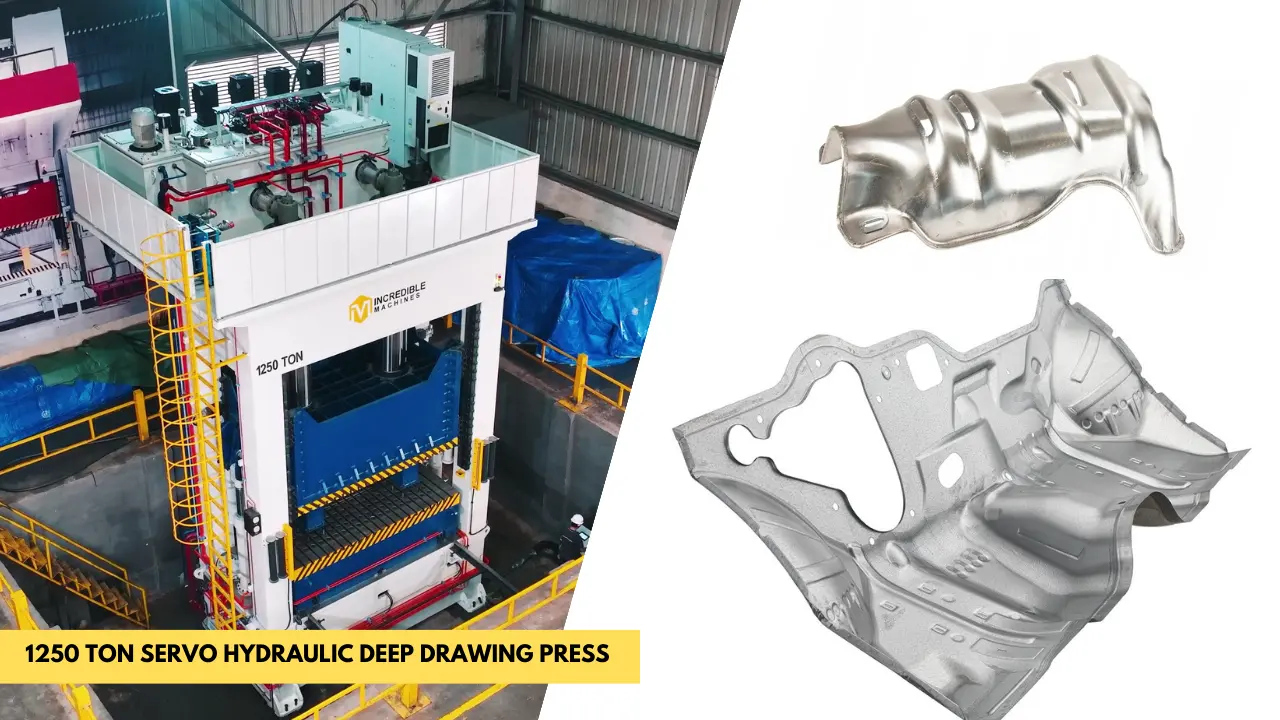

At Incredible Machines, we specialize in custom-built hydraulic presses engineered for high-performance fuel tank manufacturing processes, including deep drawing, trimming, flanging, and leak-proof forming. Our presses ensure tight tolerances, consistent quality, and efficient production cycles for OEM and aftermarket suppliers.

Applications & Use Cases

Automotive Industry

Key Advantages of Fuel Tanks Manufactured with Our Presses

1. Superior Strength and Durability

- Deep drawing technology ensures uniform material thickness.

- High forming pressure enhances structural integrity.

- Suitable for both crash-resistant and high-capacity designs.

2. Leak-Proof, Safety-Compliant Design

- Precision forming eliminates micro-cracks and weak points.

- Compatible with post-forming welding and sealing processes.

- Conforms to global automotive safety standards.

3. Flexible Material Capability

- Works with steel, aluminum, and composite sheets.

- Adjustable press parameters for different grades and thicknesses.

- Reduces material wastage while maintaining performance.

Applications in the Automotive Industry

Our presses are used by automotive OEMs and component suppliers to manufacture:

- Passenger car fuel tanks

- Commercial vehicle fuel tanks

- Off-highway and agricultural machinery fuel tanks

- Specialty high-performance fuel tanks