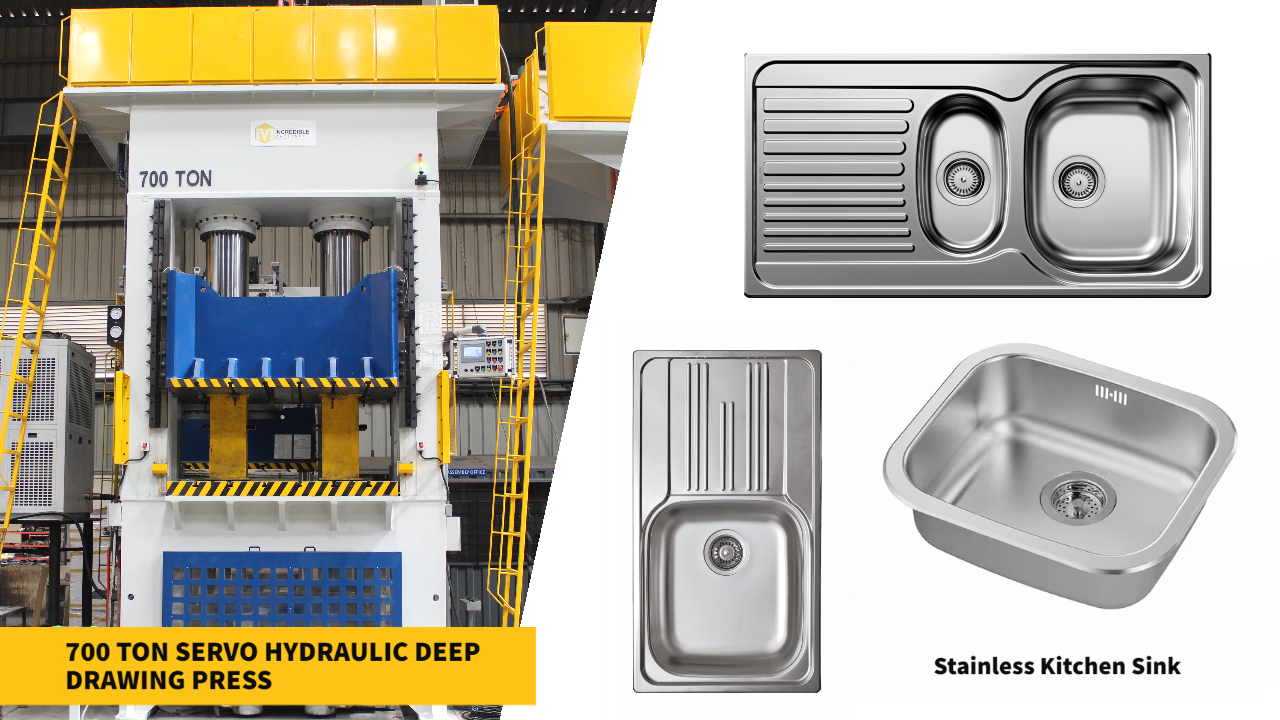

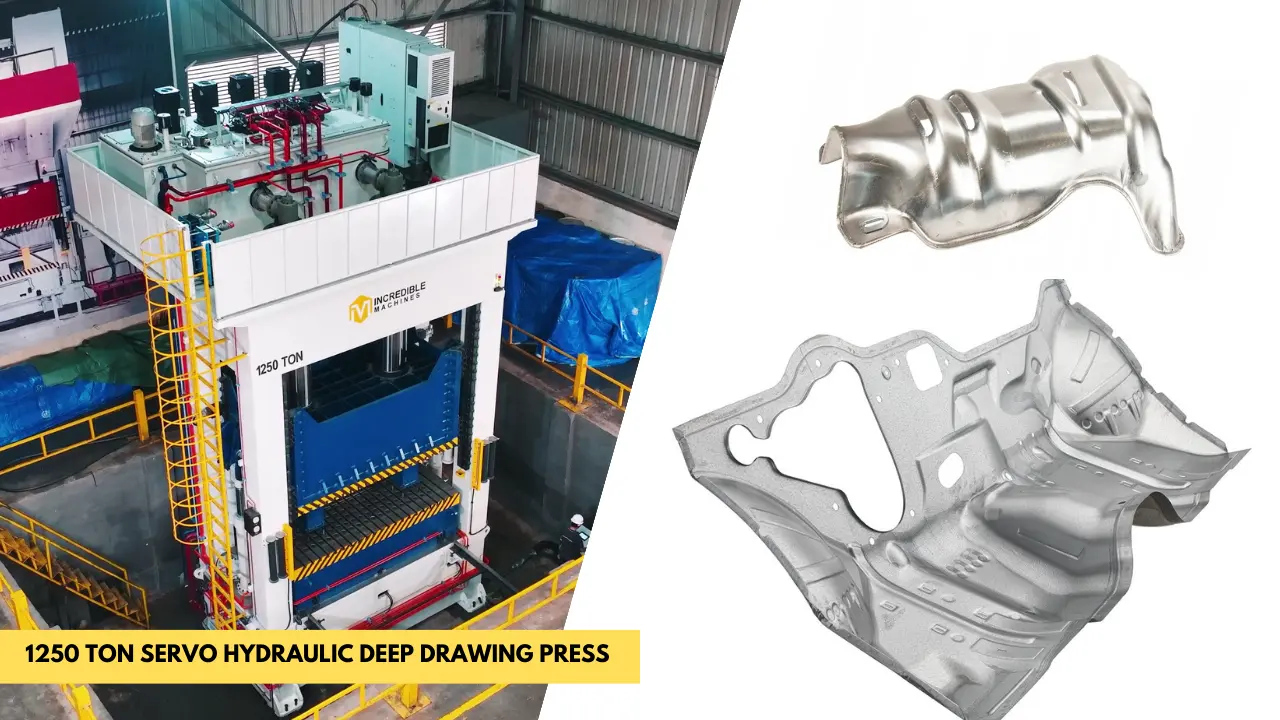

Deep Drawing Hydraulic Press for Manufacturing of SS Lids

Deep drawn to achieve high pressure resistance and reliable sealing, these lids are designed to integrate effortlessly with safety locks and gasket systems. Suitable for both household and commercial-grade pressure cookers, they offer exceptional heat endurance and structural integrity.

Applications & Use Cases

Pressure Cookers

Videos

Locking Handles with Central Rivet

Designed to withstand repeated mechanical stresses, the handles are riveted or press-fitted using precise force control. This ensures secure locking action, safe user handling, and long-term durability under pressure.

Key Characteristics:

- Wrinkle-free, crack-free material flow during forming

- Tight dimensional tolerances for leak-proof sealing

- Clean surface finish, compliant with food-grade standards

- Designed for compatibility with pressure safety valves

- Supports post-processes like polishing, laser marking, and engraving

Where These Components Are Used:

- Cookware Manufacturing — Pressure cookers, multipurpose cooking vessels

- OEM Appliance Suppliers — Contract-based component production

- Metal Packaging — Pressure lids, dome caps, and enclosures for sealed containers

Precision-Formed. Safety-Ready.

Each stainless steel lid and handle reflects the high standards required in critical kitchenware applications. Through advanced deep drawing technology, these parts are manufactured to deliver safety, strength, and reliability — straight from the press, batch after batch.