Valve Sheets – Precision Engineered for Maximum Performance

Valve sheets are critical components in various industrial systems, including automotive engines, compressors, and oil & gas equipment. They play a vital role in ensuring leak-proof sealing, controlled fluid or gas flow, and long service life.

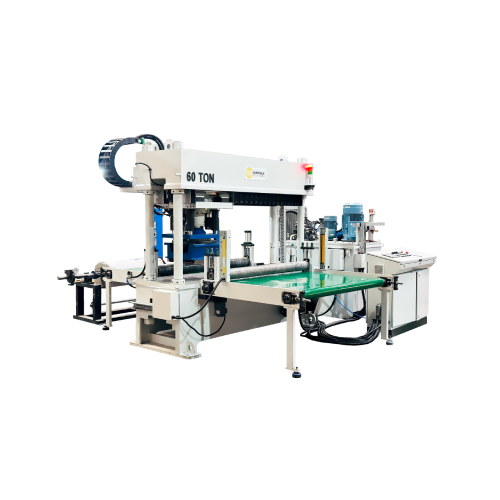

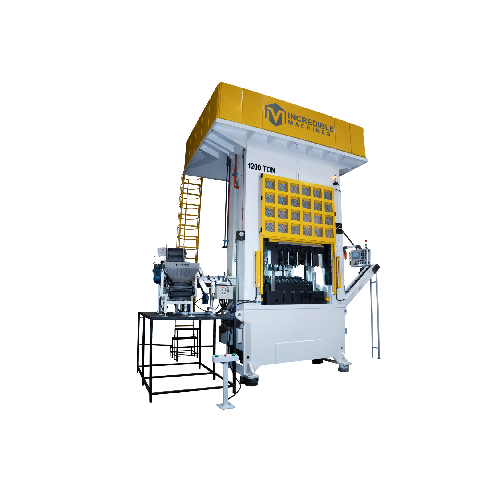

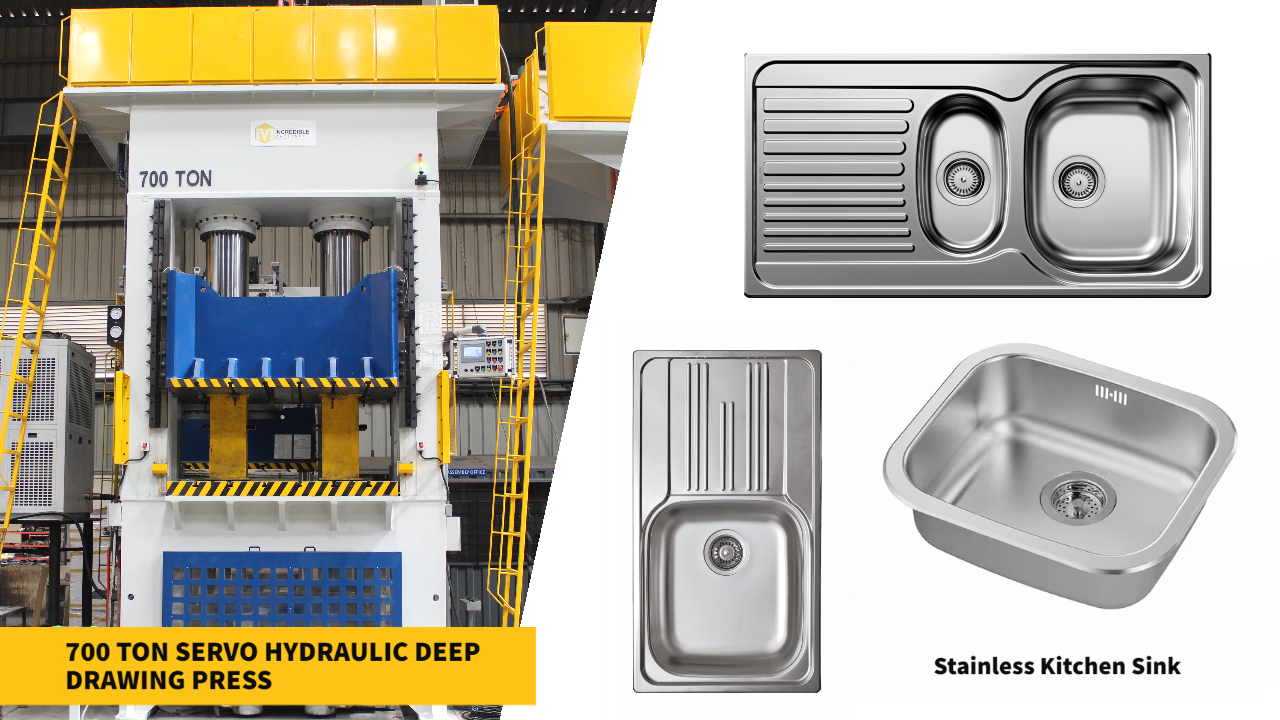

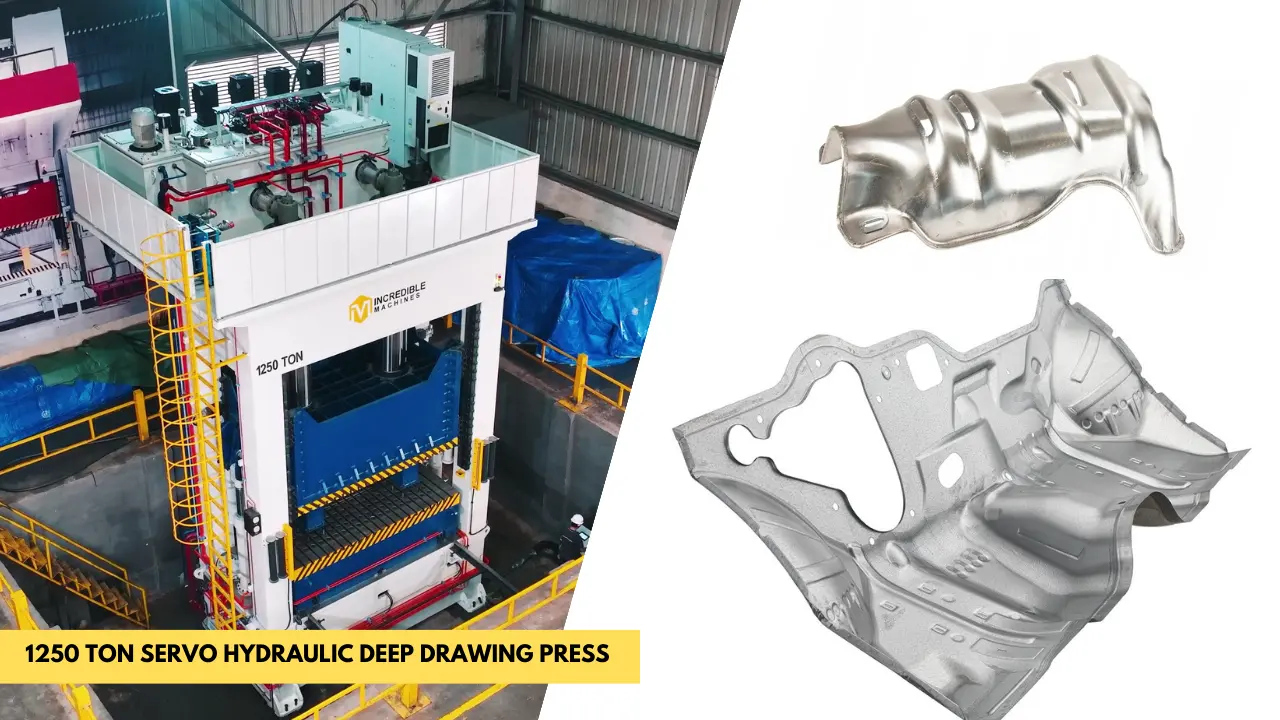

To meet these demanding performance requirements, valve sheets must be manufactured with extreme precision and uniformity — which is where our custom-built hydraulic presses excel.

Applications & Use Cases

Valve Sheets

Applications of Valve Sheets

- Automotive Industry: Used in fuel systems, cylinder heads, and engine assemblies.

- Oil & Gas Sector: For high-pressure sealing in pipelines, valves, and drilling equipment.

- Industrial Machinery: Ensuring reliable operation in pumps, compressors, and fluid control systems.

Advantages of Manufacturing Valve Sheets with Hydraulic Presses

- Consistent Accuracy – Uniform pressure distribution ensures perfect dimensions every time.

- Material Versatility – Works with metals, composites, and high-performance polymers.

- High Repeatability – Ideal for mass production with minimal tolerance variation.

- Surface Perfection – Achieves smooth finishes and defect-free surfaces.

- Customisation Capability – Easily adaptable for different valve sheet designs and sizes.

Whether you need single-station presses for prototyping or fully automated systems for mass production, our expertise ensures that every valve sheet you produce meets the highest industry standards.