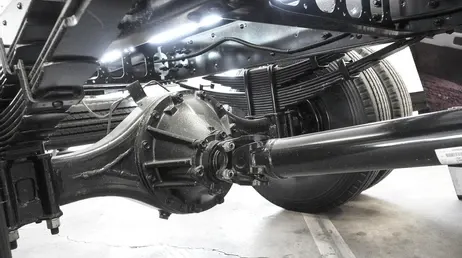

Automotive Axle Housing

An automotive axle housing is the structural casing that encloses and protects the axle shafts, differential, and related components. It plays a crucial role in maintaining proper wheel alignment, transmitting power from the drivetrain, and withstanding heavy loads and road stresses.

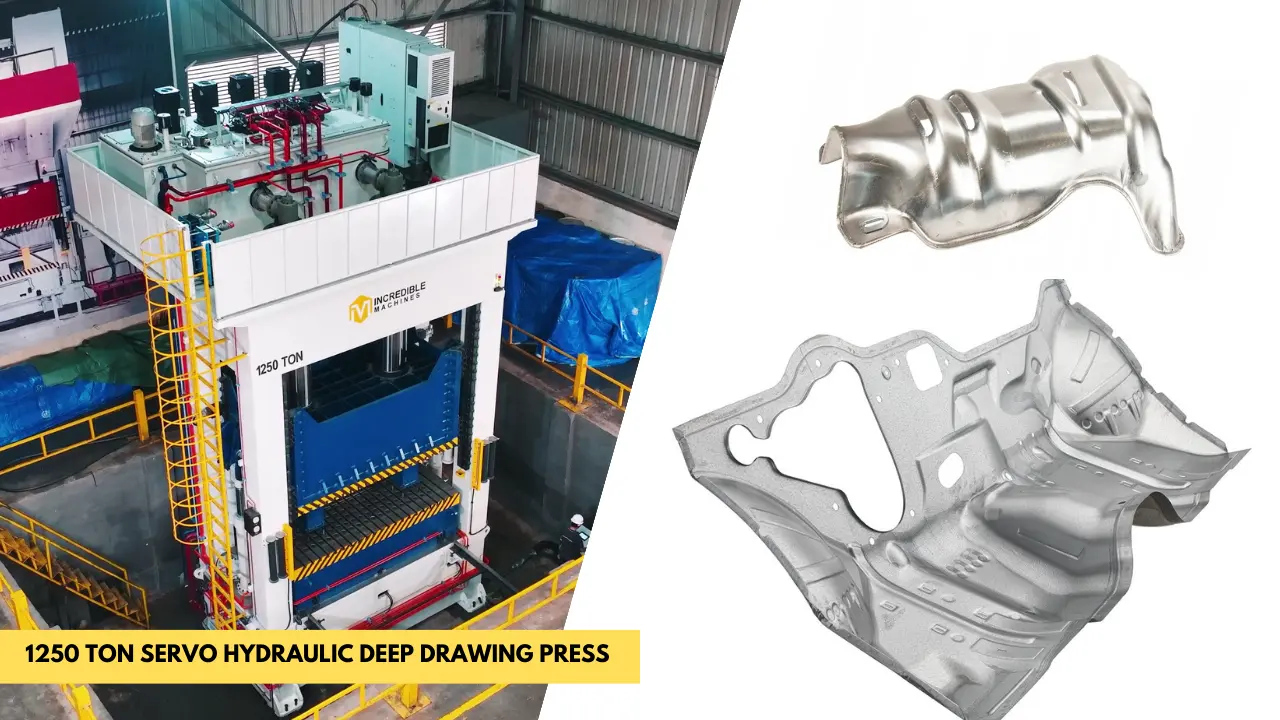

Precision in manufacturing axle housings is essential for ensuring proper fit, smooth operation, and long-term durability. That’s why leading automotive manufacturers rely on our deep drawing presses with moving bolster to form axle housings with unmatched accuracy and consistency.

Applications & Use Cases

Automotive Industry

Why Our Presses are Ideal for Axle Housing Production

- Precision Forming – Maintains tight tolerances for exact fitment with gears and axle shafts.

- High Strength Capability – Efficiently forms high-strength steel used in heavy-duty automotive applications.

- Consistent Quality – Servo and hydraulic control systems deliver repeatable, uniform results across production runs.

- Production Efficiency – Moving bolster system speeds up die changes, reducing downtime.

- Optimized Process – Minimizes material wastage and reduces overall manufacturing costs.

Applications of Automotive Axle Housings Produced in Our Presses

- Passenger Cars & SUVs – Lightweight yet strong housings for comfort and performance.

- Commercial Trucks & Buses – Heavy-duty housings designed to carry high payloads.

- Off-Road & Utility Vehicles – Durable housings that withstand rough terrain and extreme conditions.

- Special Vehicles – Custom axle housings for defense, construction, and mining vehicles.

By manufacturing axle housings on our presses, producers achieve the dimensional accuracy, surface quality, and mechanical strength required to meet global automotive industry standards.