Precision Compaction Technology for Advanced Powder Forming Applications

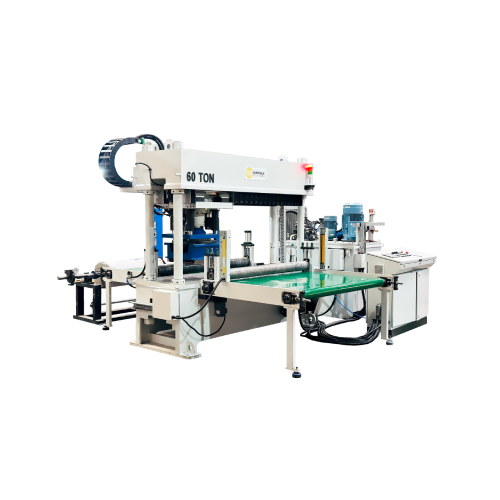

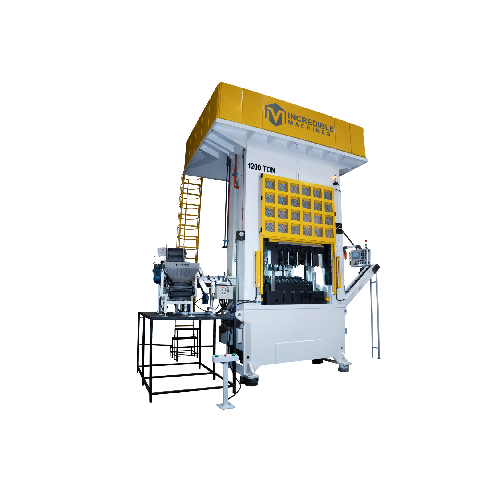

At Incredible Machines Pvt Ltd, we specialize in the design and manufacture of high-performance hydraulic compaction presses tailored for diverse industrial applications. Engineered for accuracy, repeatability, and process efficiency, our presses support the compaction of metal powders, ceramics, refractories, PTFE, composites, and other advanced materials. Whether you're producing structural components, ceramics, or high-temperature refractories, our single or multi-action powder compacting presses deliver consistent results under demanding production environments.

Applications & Use Cases

Aluminium Sintered Parts

Automotive Sintered Parts

High Aluminium Ceramics

Self Lubricating Bearing

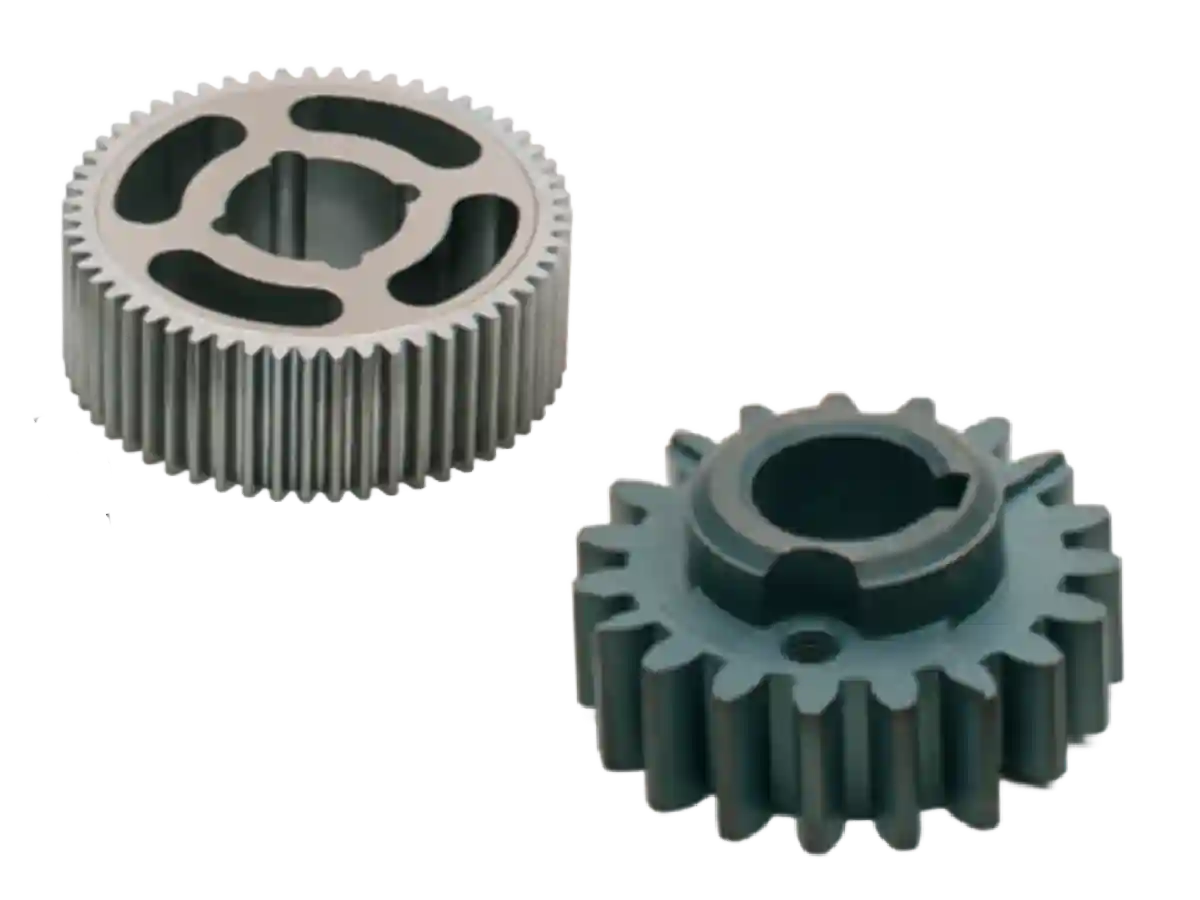

Sintered Gear

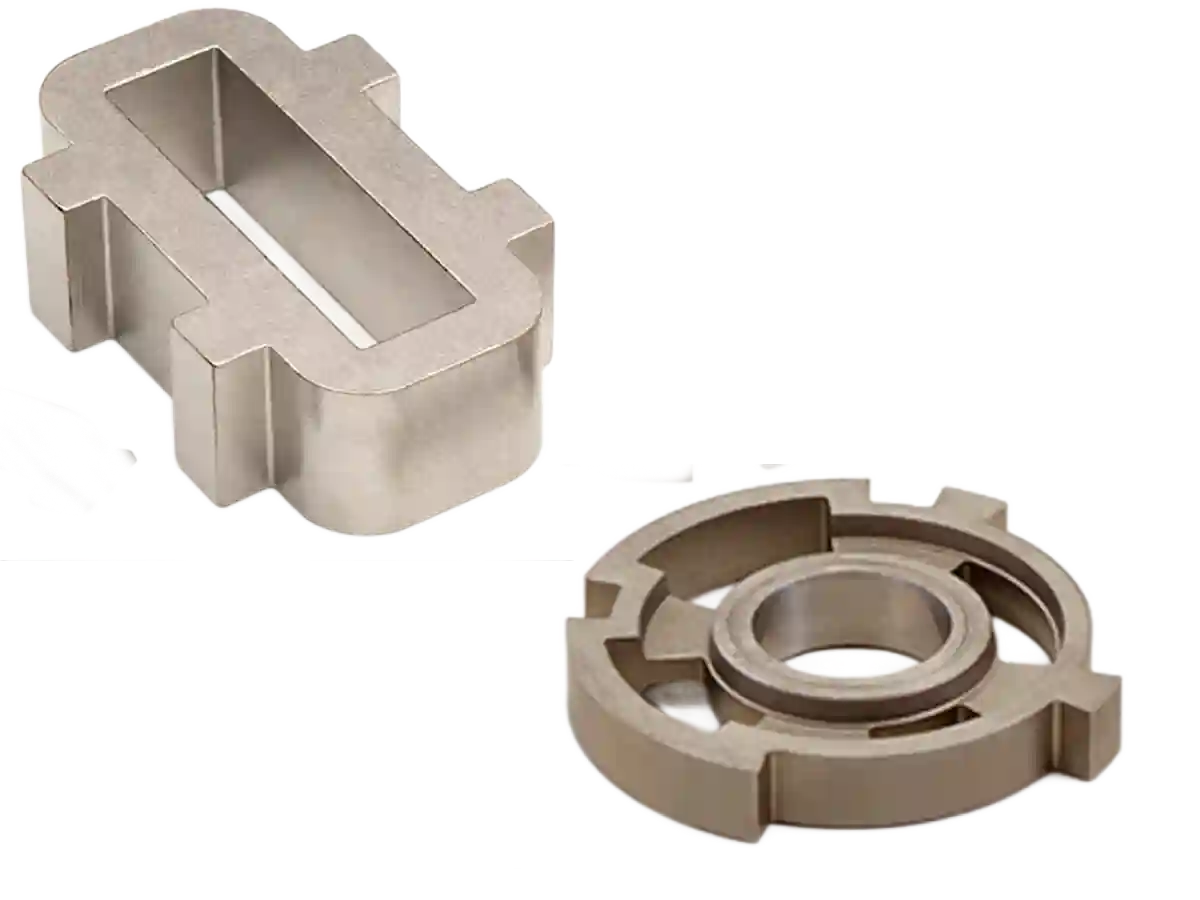

Soft Magnetic Sintered Parts

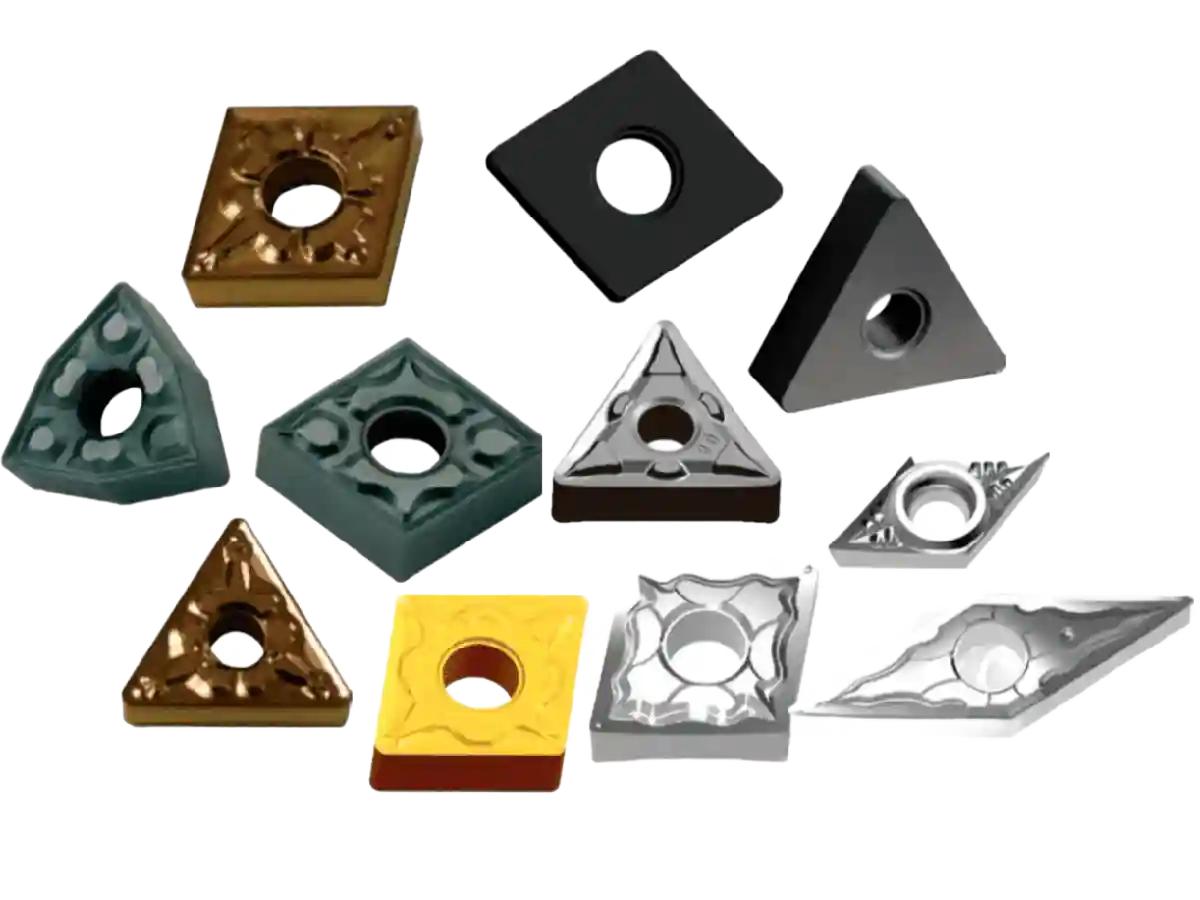

Tungsten Carbide Tools

Valve Seat Insert

Videos

Advanced Press Design for Custom Compaction Needs

Every compaction application has unique demands—specific compaction pressures, fill depths, tooling configurations, and powder behaviours. Our compaction presses are engineered to adapt to these parameters with:

- Tonnage capacity ranging from 35 Ton to 1000 Ton and above

- 4-Column or 4-Pillar rigid structures built to JIS B6403 standards

- Multi-platen architecture (available in configurations like 1 Upper / 1 Lower to 3 Upper / 4 Lower)

- Monolithic frame options for extra rigidity in high-tonnage applications

These robust mechanical platforms ensure uniform force distribution, dimensional stability, and long operational life even under continuous operation.

Full-Featured Compaction Solutions

To deliver the highest precision and flexibility, our compaction presses are offered with a wide array of advanced features, including:

Automatic Powder Feeders: Improve throughput by enabling consistent fill volumes and faster cycle times.

Floating Cavity Platens: Ensure uniform powder distribution and homogeneous green part density.

Servo Systems: Enable high-precision platen movement, accurate pressure control, and energy efficiency.

Die Withdrawal Systems: Facilitate smooth and damage-free ejection of formed parts.

Multiple Filling Modes: Selectable via HMI for different powder characteristics and part geometries.

Auto Lubrication System: Reduces wear, extends component life, and supports uninterrupted production.

Dynamic CNC Controls: Manage individual platen movement and coordinate multi-action operations for complex part geometries.

HMI-Based Operator Interface: Easy-to-use interface with recipe management, diagnostics, and parameter tuning.

Production Monitoring: Integrated systems for generating daily, weekly, and monthly production reports for traceability and process optimization.

Integrated Safety Mechanisms: Includes physical guards, light curtains, interlocks, and emergency stop features for operator safety.

Applications Across Industries

Our powder compaction presses are widely used in the production of a variety of components across multiple industries. Some of the key application areas include:

Refractory Brick Compaction: For forming high-density refractory bricks used in furnaces, kilns, incinerators, and steel plants. These presses ensure uniform material distribution, accurate geometry, and excellent compaction strength.

Metal Powder Compaction (Automotive): Used to form automotive components like gears, bushings, and structural parts using ferrous or non-ferrous metal powders.

Ceramic Powder Compaction: For tableware, sanitaryware, and tiles, delivering flawless surface finish and density integrity in the green state.

Technical & Bio Ceramics: For electronics, medical implants, filters, and insulators where micro-level accuracy and density consistency are vital.

Magnetic Material Compaction: Enabling high-precision pressing of magnetic powders used in motors, transformers, sensors, and medical imaging equipment.

Tantalum & Exotic Powders: Used in pharmaceutical, nuclear, and chemical processing sectors where special materials are compacted for corrosion resistance or high-performance characteristics.

Engineered for Precision. Designed for Reliability.

Our compaction presses combine rugged mechanical design with intelligent automation, delivering unmatched performance and flexibility. Every machine is designed to be:

- Modular and Scalable to grow with your production needs

- Compatible with Manual, Semi-Automatic, and Fully Automatic Operation Modes

- Ready for integration with Robotics, Conveyor Systems, and other automation infrastructure

- Equipped for In-Process Quality Monitoring and minimal maintenance downtime

Whether you're compacting single-cavity precision parts or high-volume multi-cavity components, our solutions are engineered for performance, productivity, and quality assurance.

Why Choose Incredible Machines for Compaction Presses?

- Custom-built solutions tailored to your material and application

- High-tolerance assemblies for consistency in green part density

- Industry 4.0 compatibility with data logging, remote monitoring, and predictive maintenance

- Energy-efficient hydraulic and servo-hybrid systems

- Proven expertise in handling complex compaction challenges

- Strong service and support infrastructure across domestic and international markets

Let’s Engineer Your Ideal Powder Compaction Solution