At Incredible Machines Pvt. Ltd., we design and manufacture next-generation Servo Electric Powder Compacting Presses that combine accuracy, speed, and efficiency to deliver consistently superior green parts. By replacing traditional hydraulics with advanced servo-electric systems, our presses ensure energy efficiency, precise control, and minimal downtime—making them the perfect choice for industries that demand uncompromising quality.

Applications & Use Cases

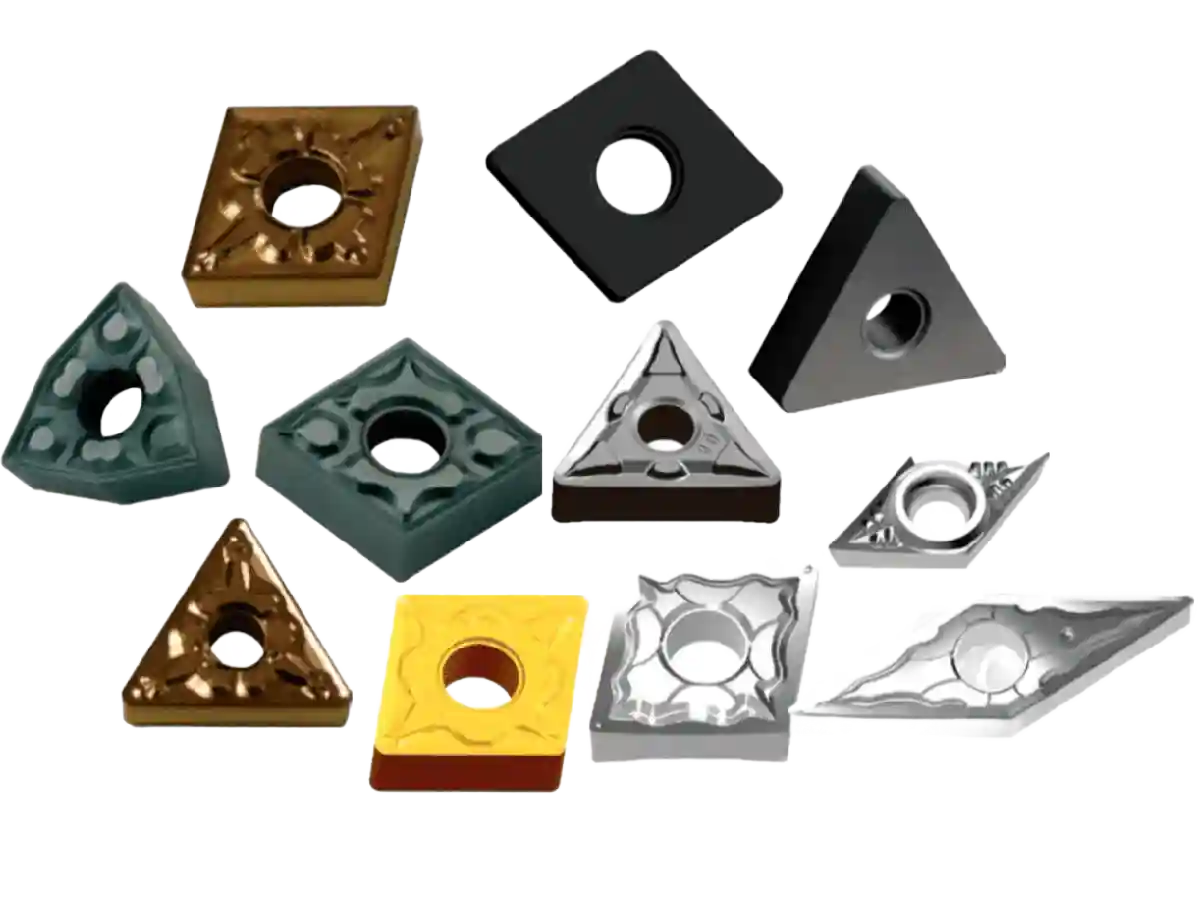

Tungsten Carbide Tools

Valve Seat Insert

Videos

Key Features & Benefits

1. Precision-Controlled Filling & Ejection

Both filling height and ejection height are controlled by high-performance servo motors, ensuring accuracy at every cycle. These parameters can be stored and retrieved easily via the HMI interface, minimizing setup time for repeat jobs.

2. High Load Capacity Screw Design

The press incorporates a heavy-duty screw system with superior load-bearing capacity, which reduces machine downtime and enhances operational reliability.

3. CNC-Controlled Closed-Loop Axis

Our closed-loop CNC system synchronizes the movement of all platens, ensuring uniform density and precise dimensions of the component. This advanced control maintains accuracy without compromising speed.

4. Servo-Controlled Powder Feeding

A servo-driven powder feeder guarantees precise powder dosing, maintaining consistent component weight and reducing variability in production.

5. Auto Weight Correction

With intelligent auto weight correction, the system adjusts powder feed dynamically, significantly lowering the rejection rate and ensuring higher yield.

6. Faster Production Cycles

Unlike hydraulic presses, the servo-electric design eliminates delays caused by hydraulic on/off cycles, resulting in much faster and smoother production.

7. Smart Production Reporting

Daily, weekly, and monthly production reports can be generated directly through the HMI and accessed remotely via IoT connectivity. This enables complete transparency and better production planning.

8. IoT-Enabled Remote Monitoring

Our press is equipped with IoT-based remote health monitoring, allowing predictive maintenance, reducing unplanned downtime, and extending machine life.

Applications

The Servo Electric Powder Compacting Press is widely used in industries requiring high-density, precision components such as:

- Automotive & EV

- Electrical & Electronics

- Aerospace & Defence

- Medical Components

- Tools & Hardware

Why Choose Incredible Machines?

With our extensive experience in designing high-tonnage precision presses, Incredible Machines Pvt. Ltd. delivers more than just equipment—we provide reliable solutions that enhance your production quality, efficiency, and profitability. Every press is engineered with a focus on long-term performance, safety, and after-sales support.

Experience the future of Powder Metallurgy with our Servo Electric Powder Compacting Presses – where accuracy meets efficiency.