Precision in Every Press: Exploring the World of Incredible Machines Pvt Ltd

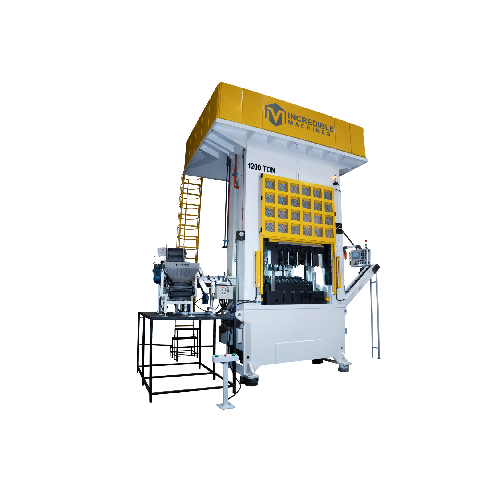

In the dynamic landscape of manufacturing, precision, reliability, and innovation are not just desired; they are essential. At the heart of producing high-quality components for a vast array of industries are sophisticated machines capable of shaping metals and materials with unparalleled accuracy. This is where Incredible Machines Pvt Ltd, based in Rajkot, India, stands out as a leader, renowned for its expertise in designing, manufacturing, and delivering world-class hydraulic presses and automation solutions. With a compelling tagline, "Pressing with Precision", the company encapsulates its core philosophy: delivering machinery that performs flawlessly under pressure, every time.

A Vision for Global Leadership

The vision of Incredible Machines Pvt Ltd is clear and ambitious: to be a global leader in designing, manufacturing, and delivering world-class hydraulic presses and automation solutions. This aspiration is underpinned by a commitment to setting new benchmarks in quality, innovation, and customer satisfaction. The company strives to exceed customer expectations not just through cutting-edge technology, but also by offering comprehensive turnkey solutions and superior after-sales service. This holistic approach is aimed at building long-term partnerships across diverse industries worldwide.

From Humble Beginnings to Manufacturing Giant

The journey of Incredible Machines began modestly in 2003 in Rajkot. Initially operating from a small facility, the company started with a diverse machinery portfolio. However, identifying a core strength and market need, they soon pivoted to focus only on Hydraulic Press Machines, concentrating on Higher Capacity & Customization. This strategic focus allowed them to build deep expertise in this specific domain.

Growth was rapid and significant, marked by key facility expansions. In 2008, the company expanded to a new 60k Sqft facility, enabling them to cover a larger market and achieve record-breaking turnover. This growth trajectory continued, leading to another major expansion in 2016 to a 200k Sqft new facility. This expansive facility is notably described as India’s largest facility for Hydraulic Press Manufacturing, a testament to their scale and ambition in the industry.

Today, Incredible Machines Pvt Ltd is a powerhouse in the manufacturing sector. Incorporated in 2003, the company recorded a Last Year Turnover of INR 100 Cr and boasts a robust Growth Rate of 40%+ Y-o-Y. Their team comprises over 300+ Members, contributing to the design, manufacturing, and support of their advanced machinery.

Impressive Scale and Global Reach

The scale of Incredible Machines' operations is remarkable. Their plant area spans over 2,00,000 + Sq Ft, housing 30+ Advanced Machines for in-house manufacturing. This capability allows them to maintain stringent quality control and deliver precision-engineered products.

Their impact is felt globally, with more than 1000+ Machines Installed Across India and Overseas market. Incredible Machines has successfully established its footprint in more than 10 countries, achieved through numerous successful supply and installation projects across diverse industries. This expansion is driven by a commitment to "Taking Innovation Worldwide" and "Expanding Global Footprint".

A key indicator of customer satisfaction and product reliability is the fact that Every year more than 70% of their revenue is driven by their existing customers. This high percentage of repeat business underscores the trust and long-term partnerships they build with clients.

A Diverse Range of Precision Hydraulic Presses

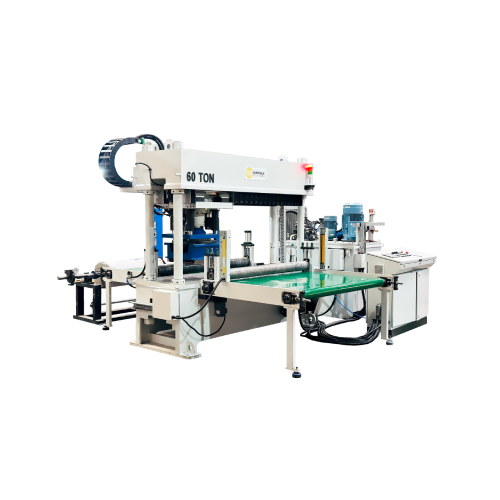

Incredible Machines Pvt Ltd offers a comprehensive portfolio of hydraulic presses, designed to meet the specific needs of various metal and non-metal forming applications. Their presses cover a wide range of capacities, from 10 to 5000 Tons and above. The product range includes:

- Deep Drawing Press:

- Hot & Cold Forging Press:

- Composites Hot Moulding Press:

- Powder Compacting Press:

- Thermoforming Press:

- Die Spotting & Tryout Press:

- Trimming Press (SPM):

- Hydraulic Metal Forming Press:

- Multi Daylight Heating Press:

This diverse range showcases Incredible Machines' capability to provide solutions for a wide spectrum of manufacturing needs, from intricate drawing to heavy-duty forging and specialized moulding and compacting processes.

State-of-the-Art Infrastructure: The Backbone of Precision

The 2,00,000+ Sq Ft Facility in Rajkot is not just a manufacturing plant; it's a sophisticated ecosystem designed for precision engineering and high-volume production. This vast infrastructure houses various critical departments, each equipped with advanced machinery and processes to ensure quality at every stage:

- Fabrication: The foundation of robust press structures is laid here, utilizing 35 MIG Welding machines.

- Design Team: Comprising 20+ People, this team is the innovation hub, equipped with Solidworks Software and leveraging a database of over 1200+ Machines Data. They employ FEA Analysis to ensure structural integrity and optimal performance of each press design.

- Profile Cutting: Precise preparation of materials is critical. This is handled by 2 CNC Plasma Cutting Machines and 2 CNC Oxyfule Cutting Machines.

- Machining: This department is equipped to handle components of various sizes and complexities, featuring 4 Double Column VMCs (up to 5x3 Mt), 3 Floor Boring machines (up to 8x4 Mt), 6 3 Axis VMCs, CNC Lathe Machines, HMC Machines, and Surface Grinders. This extensive setup allows for high-precision machining of large and intricate parts in-house.

- Shot Blasting Chamber: Equipped with a Full Floor Auto Recovery System, this chamber ensures proper surface preparation before painting, crucial for the longevity and finish of the machines.

- Painting: The finished machines receive a high-quality finish using PU Coated Painting and Spray Painting techniques.

- Quality Checking: Rigorous quality control is applied throughout the manufacturing process. Adherence to standards like Geometrical Accuracies JIS B6403 Grades is verified using a range of precision tools including Ultra Sonic Testing, Dial Gauges, Vernier Calipers, Micrometers, Surface Gauges, and Filler Gauges. The sources also indicate a Certificate Testing Process By Incredible Machines Pvt Ltd, highlighting their commitment to verifying machine performance and quality.

- Assembly: Dedicated, Parted Assembly Areas facilitate the organised assembly of complex machinery. The facility is equipped with 16 Overhead Cranes with significant lifting capacities, ranging from 5 Ton, 10 Ton, 30 Ton, 40 Ton, up to 100 Tons, enabling the handling of massive press components. A Pit for Big Machines further aids in the assembly of very large presses.

- Dispatch: The final stage involves meticulous preparation for delivery. This follows a defined Dispatch SOP, including Packing, Welding Support, and careful Load Balance. The facility is equipped with a 200 Ton Weigh Bridge to manage shipments effectively.

This detailed infrastructure underscores the company's capability to manage the entire process, from design and fabrication to machining, assembly, and dispatch, all under one roof in their state-of-the-art facility.

Exceptional Service and Customer Partnerships

Beyond manufacturing prowess, Incredible Machines places a strong emphasis on customer satisfaction and support. They have established an effective and strategically positioned service network across India, ensuring prompt and efficient support for customer compliance. This network is complemented by a commitment to Rapid response time to address customer queries and technical challenges.

The company believes in proactive support, offering Proactive maintenance and support for uninterrupted operations. Their support is delivered by Skilled and trained professionals providing expert assistance. This dedicated approach to service, combined with the quality of their products and seamless installations, has been instrumental in Earning the trust of global customers. This commitment to partnerships and support is a significant factor behind the high percentage of revenue generated from existing clients.

Conclusion: A Partner in Precision Manufacturing

Incredible Machines Pvt Ltd, located in Rajkot, has evolved from a humble beginning to become India's largest facility for Hydraulic Press Manufacturing. Their journey is marked by strategic focus, continuous expansion, and a relentless pursuit of excellence in hydraulic press and automation solutions.

With a diverse range of presses catering to numerous applications, a state-of-the-art 2,00,000+ sq ft infrastructure supporting in-house manufacturing, and a strong global footprint with a dedicated service network, Incredible Machines is well-positioned to meet the demanding needs of modern manufacturing industries worldwide. Their vision of being a global leader and their proven ability to build long-term partnerships based on trust, quality, innovation, and superior service make them an ideal partner for companies seeking precision and reliability in their pressing and forming operations.

Choosing Incredible Machines means opting for a partner with a proven track record, a comprehensive product line, unparalleled manufacturing capability, and a genuine commitment to customer success – truly "Pressing with Precision".