Pressing with Precision: Essential Factors When Choosing a Hydraulic Deep Drawing Press

When investing in machinery as critical as a hydraulic deep drawing press, manufacturers need to carefully evaluate several factors to ensure they select a system that delivers precision, reliability, and efficiency. Incredible Machines Pvt Ltd, a company with decades of experience in supplying custom heavy-duty hydraulic presses, press lines, and automation solutions, offers insights into what makes a world-class hydraulic press system. Drawing upon their expertise and the features highlighted in their materials, here are the key considerations:

1. Understanding the Manufacturer's Capabilities and Experience

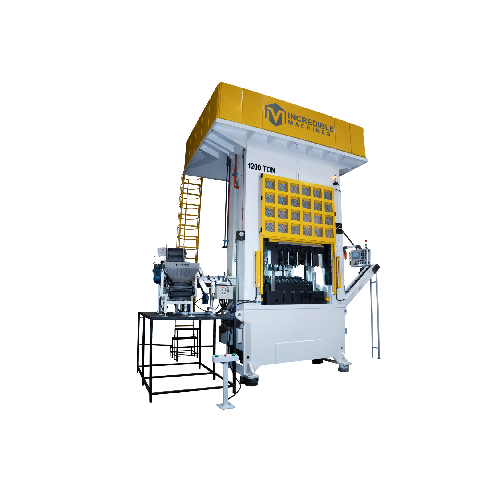

Choosing a manufacturer with a proven track record is paramount. Incredible Machines, for example, was incorporated in 2003 and has built a strong reputation for delivering value. Their state-of-the-art plant in Rajkot, Gujarat, is noted as one of India’s biggest facilities for producing hydraulic presses. With a team size of 250+ members and complete in-house manufacturing capabilities, they demonstrate significant operational capacity. Their history shows growth from a humble beginning with a small facility to expanding to a 60,000 Sq Ft facility and then to the current 2,00,000 Sq Ft facility. They have installed over 1000+ machines across India and overseas markets and report over 60% repeat business from existing customers, indicating strong customer satisfaction and reliability. This level of experience and infrastructure is crucial for designing, manufacturing, and servicing hydraulic presses effectively.

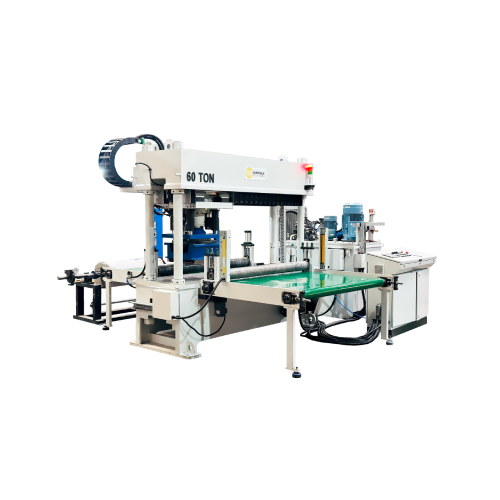

2. Press Specifications and Capacity

Hydraulic presses come in a wide range of tonnages, and selecting the correct capacity is vital for your specific deep drawing applications. Incredible Machines offers hydraulic presses from 10 to 5000 tons and beyond. Considering the size of parts you intend to draw and the material thickness will help determine the required tonnage.

3. Advanced Design and Structural Engineering

The foundation of a quality press lies in its design and structure. Look for manufacturers utilizing the latest design technologies. Incredible Machines uses 3D modeling and finite element analysis (FEA), enabled by a dedicated engineering team of 15 people using Solidworks Software. FEA specifically helps ensure optimal deflection under full load.

The structural rigidity is critical for maintaining precision during the deep drawing process. Incredible Machines emphasizes high-standard design for excellent rigidity and minimal deformation. Their presses often feature a Single-piece Monolithic Structure which enhances stability and reduces distortion. Designs like the Window Cut H-Frame are highlighted, offering both rigidity and improved accessibility. Reinforced sections further increase durability. A rigid structure is fundamental to achieving the required accuracy and consistency in deep-drawn parts.

4. Precision Guiding System

The slide's movement within the press frame must be exceptionally accurate and stable to produce consistent deep-drawn parts without defects. Incredible Machines employs an 8 Point GIB Guiding System which ensures extreme stability and robust performance. The guiding bars are made of C45 material and undergo specific process steps including Planning, VMC Machining, Induction Hardening, and Grinding.

Key features of this system include:

- Replaceable Phosphorus Bronze Liner: This facilitates easy maintenance.

- Accurate & Smooth Slide Movement: This directly enhances precision and efficiency.

- Enhanced Balance & Precision: Ensures reliable operation.

- Convenient Operation in Eccentric Forces: The system is designed to handle off-center loads effectively, which is often encountered in deep drawing of complex shapes.

- Specially Designed Bolting System: Provides firm gripping of the guiding bar. This bolting system is precision-engineered for secure attachment and equipped with low-pitched bolts allowing for meticulous adjustment and alignment of the guiding system.

- Grooving & Wiper Seal: High-precision grooves ensure proper lubrication in the guiding system, while wiper seals maintain a dust-free guiding system.

This detailed focus on the guiding system directly impacts the accuracy and longevity of the press, crucial for high-quality deep drawing.

5. Hydraulic System Quality and Components

The heart of a hydraulic press is its hydraulic system. The quality of components and circuit design significantly influences performance, reliability, and efficiency.

- Hydraulic Cylinder Ram: The ram should be durable. Incredible Machines uses an Induction Hardened Cylinder Ram which ensures long life and durability, offers scratch protection, and is Grinded and Hard Chrome Plated for smooth operation. The Ram & Piston are made of a Single Solid Rod, which is noted to prevent oil leakages for long years of working.

- Return Line Filter with Choke Indication: Proper filtration is essential for hydraulic fluid health. A system with a high-performance filter ensures optimal oil cleanliness. Indicators like a Digital Pressure Gauge and HMI Display Integration providing direct indication of filter status and choke conditions help prevent clogging and ensure reliable operation.

- Servo System: Modern deep drawing often benefits greatly from servo technology. Incredible Machines offers presses with servo-based systems and the customer list includes many SERVO HYDRAULIC DEEP DRAWING PRESS models. A Servo System (Servo Motor, Servo Drive, Servo Pump) provides High-Precision Motor Control ensuring precise positioning. It allows for Real-Time Speed and Torque Adjustment to optimize performance and reduce cycle times. Servo systems offer Consistent Performance Across Loads, maintaining process stability. Critically, they are Energy-Efficient Operation, cutting energy costs, and offer Enhanced System Responsiveness, boosting productivity.

- Specially Designed Power Pack with Logic Circuit: The power pack's design impacts efficiency and control. Incredible Machines uses an Advanced Hydraulic Circuit featuring a logic-type hydraulic oil circuit for optimized performance. This design is User-Friendly, offers Precise Control of stroke, speed, and pressure throughout the cycle, and enhances efficiency by minimizing heat generation. It also reduces risk by eliminating the need for additional piping, lowering potential leaks and system failures.

- Servo Proportional Valves: These valves are key to precise hydraulic control. They ensure Precise Flow Control and allow for Adjustable Pressure Settings for various applications. They offer Real-Time Response for immediate adjustments, contribute to Reduced Energy Consumption, and improve overall system efficiency.

- Pressure Gauge: Accurate pressure monitoring is vital. A Pressure Gauge provides Accurate Pressure Measurement and Real-Time Monitoring, allowing for immediate detection of pressure changes. A durable and easily readable gauge helps identify issues early, preventing potential damage and reducing downtime.

6. Control System and Automation Features

The sophistication of the control system directly impacts the ease of use, programming flexibility, and monitoring capabilities.

- Digital Control System: Incredible Machines' presses come with a Digital Control System that is User-Friendly and intuitive. It offers Comprehensive Control managing speed, pressure, stroke length, and positioning with precision. Features like Ample Storage (up to 100 programmable settings) and Real-Time Alerts for conditions like high oil temperature or low oil level are valuable for efficient operation and maintenance. An Advanced Data Interface with USB and Ethernet ports facilitates seamless data integration, and the system can generate Detailed Reporting (shift, hourly, daily, weekly charts) and enable Production Monitoring.

- Linear Scale And Linear Encoder: These components are crucial for accurate position feedback and control. They provide Enhanced Mapping Accuracy and Precision Measurement Up To 10 Microns. Control Stroke Length Via HMI Interface offers easy and precise adjustment.

- Digital Oil Temperature Indicator & Oil Level Gauge: Monitoring these parameters is vital for system health and longevity. The system displays real-time oil temperature and automatically stops the machine if temperatures exceed preset limits. A Low Oil Level Alarm on the HMI prevents operational issues. Proper monitoring extends the life of oil, pumps, and seals, reducing maintenance time.

- Limit Switches: These provide essential feedback on slide position. Top Dead Center Detection ensures the main slide reaches the top safely, preventing over travel. Bottom Dead Center Detection confirms the slide reaches the bottom correctly, avoiding mechanical issues. Stroke Length Monitoring verifies operation within set limits, maintaining accuracy. These switches provide enhanced safety by controlling critical positions.

- Integration with Automation: For high-volume production, integration with automated systems is key. Incredible Machines offers integration with features such as moving bolsters, servo-based systems, IoT, and automated loading/unloading solutions. They can provide complete integrated solutions including transfer devices and robotics, offering full turnkey solutions. Many customer references list presses with Moving Bolster and SERVO BASED MACHINE features.

7. Specific Features for Deep Drawing

Deep drawing presses have unique requirements compared to other types of presses. Certain features are particularly beneficial:

- Cushion System: A robust cushion system is vital for controlling material flow during drawing and preventing wrinkles or tears. While the source mentions a cushion system function with a 4-Point Guiding System for stable support and handling eccentric forces, it also details supporting components.

- Bushes for Cushion Pin Hole in Bolster: These are specific to deep drawing presses and ensure precise alignment of the cushion pin hole, reduce noise and vibration, facilitate smooth slide movement, and prevent metal-to-metal wear on the bolster plate, reducing downtime. A Waste Prevention Cover keeps these bushes free from debris.

- Hardened Block On Cushion Bed: Made of EN 31 Hardened & Grounded material, this block is crucial for preventing Cushion Pin Impressions and protecting the cushion bed from damage and deformation, extending its lifespan.

- Some customer references explicitly mention presses WITH CUSHION or WITH DIE CUSHION.

8. Quality Control and Accuracy Standards

The final quality of deep-drawn parts depends heavily on the press's accuracy and the manufacturer's quality control processes.

- Accuracy Standards: Incredible Machines states that all their presses comply with JIS B6403 Grade Accuracies. This adherence to Japanese Industrial Standards is a strong indicator of precision manufacturing.

- High Standards of Quality Control: Components are machined with high precision using advanced equipment like CNC base milling centers and boring machines. Expert testing is conducted by a specialized quality analyst team, and parameters are meticulously checked according to Japanese Industrial Standard grades.

- Accuracy Standard Inspection at Each Stage: This includes measuring Surface Flatness using a flat-approved I-beam to ensure the work table meets JIS standards, and assessing Square Travel Measurement of the slide with a calibrated round barrel and dial gauge to confirm it adheres to JIS standards.

- Greater Accuracy in terms of Tolerance: This results in Smooth, Wrinkle-Free Products, Uniform Wall Thickness, and No Breakage, directly contributing to high-quality output.

9. Safety Features

Safety is paramount in any manufacturing environment. Modern hydraulic presses should incorporate comprehensive safety measures.

- High Standards of Safety: Incredible Machines highlights maintaining high safety standards across operations.

- Safety Lock at Top Dead Center (TDC): Installed at the top dead center, this ensures maximum safety for the operator and safeguards tools by preventing unexpected movements. It engages in every cycle. Options include both manual and pneumatic locks.

- Safety Light Curtains: Utilizing advanced photoelectric sensors, these are installed on the front and back of the machine for comprehensive coverage. The machine automatically halts if an object interrupts the safety light curtain, providing an immediate response to potential hazards. Compliance with Type 2, 3, or 4 standards from reputable manufacturers is offered.

- IP55 Electrical Panel: This provides Robust Protection against dirt, dust, corrosive materials, and jets of liquids, ensuring reliable performance even in challenging environmental conditions.

- Dual Relays and Interlocks: The press is equipped with Dual Relays to enhance safety and reliability. Features include an interlock system for two-hand push buttons to prevent accidental operation and a High Oil Temperature Interlock to prevent seal failure by monitoring and responding to high oil temperatures.

10. Efficiency and Maintenance Features

Consider features that contribute to operational efficiency and ease of maintenance.

- Central Auto Lubrication with Recovery System: This system ensures consistent lubrication of sliding surfaces, facilitating smooth and safe machine operation. It reduces friction, leading to lower energy consumption, keeps the press structure clean by preventing oil spillage, and enhances worker safety by minimizing slip hazards. An oil recovery feature collects and recycles oil, contributing to cost savings and sustainability.

- Water Cooled Heat Exchanger: This helps regulate hydraulic oil temperature. A compact design saves space while providing effective cooling. High heat transfer efficiency, modular construction for easy maintenance, reduced pressure drop, and corrosion-resistant materials are beneficial features.

- IE-3 Induction Motor: Using energy-efficient motors like IE-3 reduces power losses, enhances overall system efficiency, improves performance, and lowers operating costs by decreasing electricity bills. They also ensure compliance with international energy efficiency regulations.

- Shot Blasted & Painted Surface: This process enhances surface quality for better paint adhesion, helps prevent corrosion, and extends the lifespan of coatings, contributing to the press's durability and appearance.

11. After-Sales Service and Support

A press is a significant investment, and reliable after-sales service is crucial for minimizing downtime. Incredible Machines emphasizes their exceptional after-sales service and aims to build long-term partnerships. Knowing that support is available is a key consideration when making a purchase decision.

12. Turnkey Solutions and Customization

Depending on your manufacturing setup, you might require more than just a standalone press. Incredible Machines offers presses as standalone units or fully integrated with automated systems. Their ability to provide complete turnkey solutions is a significant advantage for companies looking for a comprehensive manufacturing line. They are also capable of supplying custom heavy-duty hydraulic presses tailored to specific needs.

Conclusion

Buying a hydraulic deep drawing press requires a thorough evaluation of the manufacturer's experience, the press's specifications and capacity, the quality of its design and components, its control and safety features, and the level of after-sales support provided. Features like robust guiding systems, quality hydraulic components (especially servo technology and logic circuits), advanced digital controls, specific deep drawing features (like cushion systems and bolster bushes), stringent quality control adhering to standards like JIS B6403, and comprehensive safety measures are indicators of a high-quality machine capable of delivering precision and reliability. By carefully considering these factors, manufacturers can make an informed decision that will lead to improved manufacturing processes and high-quality deep-drawn products. Incredible Machines invites you to connect with them to explore how their solutions can meet your needs.